Crop Production

Figure 1. Crop load of Aztec Fuji apple grafted on 14 size-controlling and fire blight resistant apple rootstocks established at the Chilton REC, Clanton, Alabama, 2020.

Fire blight (Erwinia amylovora) disease management costs in apple are estimated at approximately $100 million a year in the U.S. Newly released fire blight resistant apple rootstocks can aid in disease management and improve production sustainability.

Fire Blight Resistant Rootstocks

An apple rootstock study was established at the Chilton Research and Extension Center near Clanton, Alabama (Figure 1) in 2014 as part of a multistate project aiming to assess 14 newly developed, fire blight resistant, size-controlling rootstocks grafted with a low-chill ‘Aztec Fuji’ apple.

Apple rootstocks tested in Alabama include the following newly released cultivars and controls:

- B.10

- G.11

- G.202

- G.214

- G.30

- G.41

- G.935

- G.969

- M.26 EMLA

- M.9-T337

- V.1

- V.5

- V.6

- V.7

Trees are trained to the highly efficient tall spindle training system that has not been previously tested in Alabama. The tall spindle training system is designed to control the vegetative vigor and optimize the crop production efficiency especially in the early stage of tree establishment, while providing early returns to the grower.

The major study objective is to determine the rootstock effects on tree vigor, total yield, yield efficiency, and fruit quality of ‘Aztec Fuji’ apple in Alabama conditions. The experiment is designed at a close planting distance of 5 feet by 13 feet, which equates to a total number of 672 trees/acre.

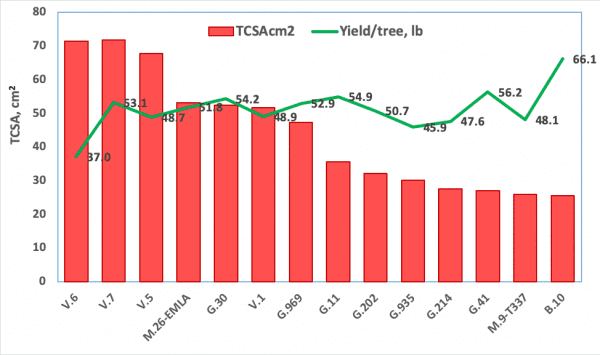

Figure 2. Rootstock effect on Aztec Fuji apple trunk cross sectional area (TCSA, red columns) and total yield per tree, (lb/tree, green line), CREC, Clanton, Alabama, 2020.

Data for tree vegetative growth presented by the trunk cross sectional area (Figure 2) demonstrate the trees grafted on the Vineland series of rootstocks V.1, V.5, V.6, V.7, as well as trees on G.30, grew very vigorously and produced large trees. On the contrary, total yield harvested from these trees was relatively low – between 37.0 lb/tree for ‘Aztec Fuji’ trees grafted on V.6 and 54.2 lb/tree for trees on G.30. Rootstocks G.214, G.41, G.935, G.202, B.10, and G.11 produced smaller trees with a heavier crop load ranging between 45.9 lb/tree for trees on G.935 and 66.1 lb/tree for ‘Aztec Fuji’ trees grafted on B.10.

Figure 3. Fruit size and appearance of Aztec Fuji grafted on G.11 grown at the CREC, Clanton, Alabama, 2020

Trees on G.11 produced the largest fruit size of 214.9 g on average (Figure 3), while the smallest trees on B.10 had the smallest fruit size of 182.9 g on average. The size difference was only numerical and not statistically significant. Soluble solids content varied between 13.5 and 15.6 percent and the fruit texture was crispy and juicy.

The sixth-year results suggest G.214, G.41, G.935, G.202, G.11 and B.10 are promising size-controlling rootstocks for Alabama conditions based on results for their yield efficiency (Table 1). The Vineland series of rootstocks V.5, V.6, and V.7 were the most vigorously growing rootstocks in the present study, and may not be a good choice of size-controlling rootstocks for establishment of high-density apple orchards in Alabama.

Research Outcomes

The outcomes of this research are expected to help enhance economic viability of Alabama apple farms through improved selection of rootstocks leading to greater production efficiency and improved fruit quality. Orchards may use labor and land more efficiently leading to a faster return on investment with fewer tree losses.

Table 1. Rootstock Effect on Aztec Fuji Apple Yield Efficiency and Fruit Quality

| Rootstock | Yield Efficiency, lb/cm2 TCSA | SSC | Fruit Firmness 1, kg/cm2 | Fruit Firmness 2, kg/cm2 | Mean Fruit Weight, g |

|---|---|---|---|---|---|

| B.10 | 0.75 | 13.8 | 4.2 | 4.0 | 182.9 |

| G.11 | 0.71 | 14.2 | 4.9 | 4.8 | 214.9 |

| G.202 | 0.82 | 13.7 | 5.0 | 5.3 | 201.8 |

| G.214 | 0.97 | 13.5 | 4.7 | 5.0 | 186.3 |

| G.30 | 0.53 | 13.5 | 4.4 | 4.5 | 193.8 |

| G.41 | 0.89 | 14.1 | 4.1 | 4.3 | 185.6 |

| G.935 | 0.87 | 13.5 | 4.5 | 4.7 | 189.0 |

| G.969 | 0.55 | 14.2 | 4.6 | 4.6 | 194.8 |

| M.26-EMLA | 0.52 | 13.6 | 4.2 | 4.2 | 191.6 |

| M.9-T337 | 1.03 | 15.6 | 5.3 | 5.5 | 186.5 |

| V.1 | 0.44 | 14.0 | 4.4 | 4.4 | 194.7 |

| V.5 | 0.43 | 13.7 | 4.6 | 4.6 | 189.6 |

| V.6 | 0.33 | 13.6 | 4.4 | 4.5 | 210.8 |

| V.7 | 0.43 | 13.8 | 4.4 | 4.5 | 199.8 |