Crop Production

High-quality transplants have a significant effect on plant performance regardless of the crop. Purchasing high-quality transplants is expensive; therefore, many growers opt to grow their own.

Transplant production for greenhouse crops is similar to that for field crops, but there are a few differences that set greenhouse transplants apart.

Growing Media

Figure 1. Components of a commercial potting mix. Vermiculite (upper right), perlite (upper left), peat moss (center). pine bark (lower right), and blended components (bottom left).

There are several options for which growing media to use, including peat-based blends and cube media.

Peat-Based Potting Blends

There are many bagged and bulk potting media available for commercial producers. Peat-based mixes provide the water-holding capacity of peat moss as well as the pore space created by other amendments such as perlite, vermiculite, and pine bark fines (figure 1). Particle sizes dictate pore space of the potting mix. Small pores are responsible for the media’s water- holding capacity; larger pores create more air space, which is essential for gas exchange as roots respire and take in oxygen.

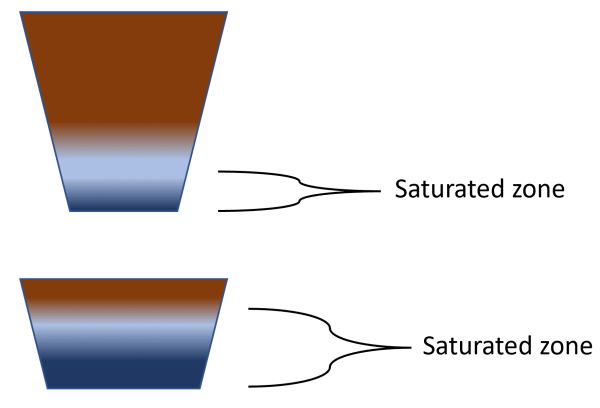

The specific physical properties of a mix will also depend on the size of the container to be used. Taller containers allow gravity to pull water to the bottom the container more readily than shallow containers do (figure 2). Packing density can also greatly affect physical properties. The tighter the media is packed when trays are filled, the smaller the pore space and the higher the water-holding capacity. It is essential to understand how these physical properties affect watering as both over- and underwatering can be detrimental to a crop.

Figure 2. Container dimensions affect water-holding capacity.

Peat-based mixes are used in conjunction with cell trays made from plastic or polystyrene materials. Cell trays are typically 10 by 20 inches, and the number of cells in a tray varies depending on the size of the cells. Larger- leaved plants, such as cucumbers, may not work well in small-celled trays but may require individual square pots. Pots that are 3 or 4 inches will allow for greater spacing to accommodate the larger leaves. Cube media

Cube media is synthetic foam or Rockwool blocks (figure 4), most of which are available in preformed sheets that fit into a standard 10- by 20-inch nursery flat. The cubes within the sheets are perforated and can be broken apart at transplanting. There are several size options, the most common size being 1-inch square.

Cube media has a high degree of airspace that helps compensate for overwatering. It is the most common media used in nutrient film technique and deep-water culture of lettuce. Larger Rockwool cubes are used for vine crop production and can be placed directly on larger slabs at planting. Unlike with other media, cube media typically does not require seeds to be covered.

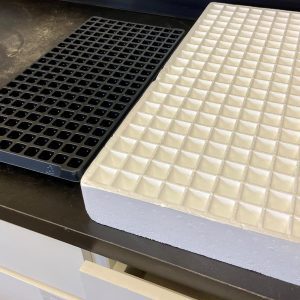

- Figure 3a. Examples of plastic and polystyrene trays.

- Figure 3b. Examples of plastic and polystyrene trays.

- Figure 4. Examples of cube media and net pots. Foam oasis cubes (left), Rockwool cubes (right), and net pots (center).

Seed Germination

Other important considerations in transplant production are the quality of seeds used and whether to direct-sow seeds or to transplant them after germination.

It is essential to buy seeds from a reputable source. A uniform and healthy stand of seedlings is directly related to seed quality. Seeds are typically dried to 10 percent moisture and can be stored in most residential refrigerators for extended periods. Seed age can significantly affect germination percentage and crop health. It is best to use seeds that are younger than 6 months old. Commercial seed distributors print the germination rate and age on the seed package. Most vegetable crops have a germination rate of 90 to 98 percent.

Germination is also affected by moisture levels in the media. Poor germination may occur if the media is waterlogged, preventing gas exchange needed for respiration. The goal is to maintain a moist environment but not a wet one.

In many cases, seeds can be sown into their final containers. If using larger containers, however, such as 3- or 4-inch pots, transplanting a seedling to the larger container is more beneficial than direct sowing. This technique is more common with tomatoes and peppers than with other crops.

Growing Transplants

Besides the potting media, four factors affect the quality of a transplant: water, fertilization, temperature, and light.

Water

Knowing when to water and how much to water is the most difficult part of growing transplants. While a lack of water can inhibit growth and be detrimental, overwatering increases disease pressure and produces leggy and spindly transplants that have poor root systems. Growing transplants on the drier side often results in fuller root systems. A quality transplant will dislodge from its cell with an intact root ball.

Fertilization

Fertilization can also significantly affect transplant quality. Most commercially bagged peat mixes have a starter charge that provides nutrients for 1 to 2 weeks after potting. Since most seedlings stay in the nursery for more than 2 weeks, use a soluble fertilizer to deliver nutrients beyond the starter charge.

Rockwool and oasis cubes do not contain any nutrients; therefore, fertilize transplants when the first true leaves appear. Venturis or injectors can be used to directly inject soluble or liquid fertilizers into the irrigation water. The amount of fertilizer depends on the injector ratio and the fertilizer type. The nutrient solution can be supplied by hand using a soft-flow water breaker or a misting system or via a flood-and-drain (ebb-and-flow) method.

Most fertilizers list the amounts to mix with water for a given injector ratio to achieve the desired rate. Parts per million (ppm) of nitrogen (N) is the standard way to express fertilizers rates for greenhouse crops, but this assumes that the grower uses a complete fertilizer. For example, 50 to 100 ppm N from a complete fertilizer (such as 20-20-20 or 20-10-20) is a standard rate for transplants. Fertilization can occur at every watering; however, use clear water after every five to six waterings to prevent fertilizer salts from accumulating in the media. Table 1 lists the amounts of fertilizer used for some common injector ratios using 20-10-20 fertilizer.

Table 1. Fertilizer Amount Needed to Achieve Given N Concentration Using 5-Gallon Stock Tank and 20-10-20 or 20-20-20 Complete Fertilizer

| Injector Ratio | Concentration (50 ppm N) | Concentration (75 ppm N) | Concentration (100 ppm N) | Concentration (125 ppm N) | Concentration (150 ppm N) |

|---|---|---|---|---|---|

| 1:16 Venturi (ounces) | 2.7 | 4.0 | 5.3 | 6.7 | 8.0 |

| 1:100 injector (ounces) | 16.6 | 25.0 | 33.3 | 41.0 | 50.0 |

| 1:125 injector (ounces) | 20.9 | 31.2 | 42.0 | 62.4 | 62.9 |

| 1:200 injector (ounces) | 33.2 | 50.0 | 66.9 | 82.0 | 100.0 |

| 5 gal no injector (g) | 5.0 | 7.0 | 10.0 | 12.0 | 14.0 |

Temperature

Most seeds germinate when night temperatures are maintained above 64 degrees F and day temperatures are above 75 degrees F. Heating mats designed for greenhouse use can be used to maintain the substrate temperature at desired levels and can also be used at cooler times of the year to speed up germination. In some cases, the use of mats might allow for a lower greenhouse heater setpoint. Keep in mind, however, that potting media will dry out much faster with bottom heating. If using heating mats, use only those designed for this purpose to reduce the risk of electrical shock.

Table 2 lists the recommended day and night air temperatures at which to grow transplants for the most common greenhouse crops.

Table 2. Optimum Greenhouse Air Temperatures and Growout Time Required for Transplant Production

| Species | Days to Germination | Weeks Before Finished | Day Temperature for Growout (°F) | Night Temperature for Growout (°F) |

|---|---|---|---|---|

| Tomato | 5 | 4–6 | 65–75 | 60–65 |

| Pepper | 7–14 | 6–9 | 65–75 | 60–65 |

| Cucumber | 3–4 | 2 | 70–80 | 60–65 |

| Lettuce | 3–4 | 2 | 55–65 | 50–55 |

Carbon Dioxide and Light

Greenhouse environments typically provide adequate levels of carbon dioxide (CO2) for seedlings up to growout. In very controlled conditions such as growth chambers or vertical farms, however, adequate CO2 must be supplied when seedlings have their first true leaves. In a greenhouse, ambient CO2 level can rise to about 400 ppm and is enough for seedling growth. During winter months when temperatures are low and greenhouse vents are shut, it becomes necessary to supplement CO2.

Adequate light must be provided when plants have their true leaves and during winter months because low light staggers seedling growth and delays production.

In a growth chamber or vertical farm, all light must be supplied. White or blue and red light-emitting diodes (LEDs) are recommended. High-pressure sodium (HPS) lamps or metal halide lamps can be used, but both are less energy efficient.

Common Transplant Crops

Some of the more common crops grown for transplant production are tomatoes, peppers, cucumbers, and lettuce. Specific details about production of these transplants is provided in the following sections.

Tomatoes and Peppers

Sow tomato and pepper seeds 1⁄4 to 1⁄2 inch below the media surface into 72-, 50-, or 36-cell trays. For larger 3- or 4-inch containers, it is best to transfer seedlings into these containers when they have one or two true leaves. These seedlings can be grown in plug trays or 1-inch cubed media. Use proper irrigation management to ensure root development.

A quality tomato or pepper transplant should have short internodes, a thick stem, and be well rooted. The height of the transplant should be one to one and a half times the depth of the container (figure 5). Transplants are ready when they reach about 6 inches in height and have five to six true leaves. Depending on the temperature and cell size, tomato transplants can take 4 to 6 weeks and peppers 6 to 9.

- Figure 5. Ideal tomato transplant with a proper shoot-to- root ratio and well-filled root system.

- Figure 6a. Newly emerged cucumber seedlings.

- Figure 6b. Cucumbers at the two true leaves stage.

Cucumbers

Cucumber transplants can take as little as 2 weeks to finish. Because of their rapid growth and large leaves, cucumbers require larger cells or even individual 3- or 4-inch containers. Sow seeds 1⁄4 inch below the media surface, and do not fertilize until true leaves emerge. Once true leaves emerge, use 50 to 100 ppm N.

Lettuce

Lettuce production requires a constant supply of seedlings; therefore, a dedicated nursery area is required for most operations. In general, the nursery area should allow for 50 percent of the transplants needed for the growout area. Pelletized seeds (figure 7) are recommended as they are easier to plant by hand or using a mechanical seeder. Some small systems use net pots with a well-drained potting media (figure 4); however, most commercial operations now use cubed-type media made from foam or Rockwool. Seeds can be grown in a lower nutrient concentration (50 to 100 ppm N) than the growout system; however, many small growers use the same concentration for seedlings and growout.

Figure 7. Pelletized seeds (right), uncoated seeds (center), and a penny for scale.

Ebb-and-flow systems allow for easy, automated watering, but hand watering one to two times a day is also effective. Use a soft-flow water breaker on a water wand to reduce damage. Transplant seedlings when they are 2 weeks old and have two to three true leaves (figure 8). Avoid using overgrown seedlings in cube media. When cubes become dislodged from the sheet at planting, many of the roots are broken off if the seedling is too big. Figure 8 shows several sizes of seedlings grown in 1-inch oasis cubes. The ideal size is the second from the right with two true leaves. The larger sizes will experience transplant shock due to damaged roots.

Figure 8. Various seedling sizes. The second from the right is the ideal seedling size.

Jeremy Pickens, Extension Specialist, Assistant Professor, Andre da Silva, Extension Specialist, Assistant Professor, and Emmanuel Ayipio, Postdoctoral Fellow, all in Horticulture, Auburn University

Jeremy Pickens, Extension Specialist, Assistant Professor, Andre da Silva, Extension Specialist, Assistant Professor, and Emmanuel Ayipio, Postdoctoral Fellow, all in Horticulture, Auburn University

New January 2023, Transplant Production for Hydroponic & Greenhouse Systems, ANR-2954