Crop Production

Sowing is one of the most important practices in the crop production process. The fundamental purpose of sowing is to place seeds at an optimum soil depth for the best seed-to-soil contact and, therefore, the appropriate growing conditions. Poor seed placement interferes with physiological processes resulting in a decrease of germination capacity, poor plant development, and, consequently, yield losses.

Before starting mechanized sowing, check your planter settings. Be sure that you have the proper selection of down pressure for the depth‐gauge wheels, closing wheel pressure, and vacuum pressure. Also be sure that the seed unit drive system and ground speed of the tractor-planter are set properly because those affect seed population, seed spacing, and sowing depth.

Maintaining seed spacing uniformity and reaching the desired depth at sowing become extremely important because the variability of both can cause variation in the plant stand. This leads to competition for light, water, and nutrients.

Achieving proper seeding depth is a major concern for all farmers, but it is more important when planting on nonirrigated areas. Under those conditions, it is necessary to find a balance between planting depth and the moisture layer in the soil.

Following are factors that can influence planting depth:

- Soil Type (Texture): Particles of sandy soil tend to be easier to break compared to particles of clay soil.

- Soil Moisture: Soil water content can reduce or increase soil resistance to penetration, which leads to shallow or deep seeding depth.

- Soil Compaction: The mechanical resistance to penetration of the sowing-cutting discs reduces cutting of the soil’s superficial surface, and, consequently, the deposition of the seeds at the desired depth.

- Downforce Mechanism: The downforce mechanism works by pushing the planter’s row unit down to the ground to keep the gauge wheel in maximum contact with the soil. If this vertical load is not sufficient to break the soil surface, the seeds can be placed too shallow.

Because of the variety of soils on field crops, it is necessary to consider the various factors mentioned above when selecting the appropriate planter downward forces according to each soil type. This will help reduce the risk of soil compaction and increase better seed deposition in the furrow.

Three main types of planter downforce mechanisms are currently on the market. They vary according to force type exerted: hydraulic, pneumatic, and mechanical by means of springs. New planters using hydraulic downforces now include an automatic mode that allows downforce changes according to the variability of the fields (soil texture, bulk density, soil moisture). This contrasts with the manual mode (only one load set) that maintains a constant pressure set by the planter operator.

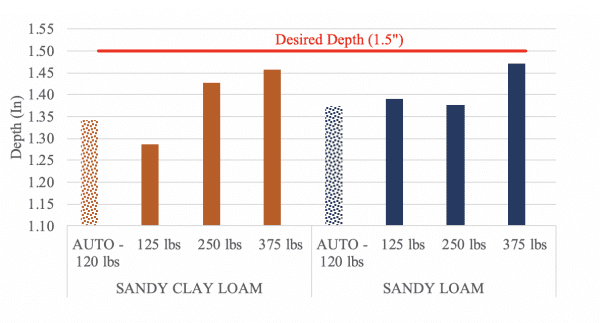

Preliminary data collected in 2019 at the E. V. Smith Research Center show that different downforces applied to different soil textures can result in different sowing depths as well as soil compaction (figures 1 and 2). A corn test conducted under dryland conditions evaluated the impact of different downforces on seeding depth, germination, and soil compaction. A six-row planter was set to plant corn at a depth of 1.5 inches on two different soil textures.

Figure 1. Differences in corn seeding depth as influenced by planter downforce and interaction with soil type. Downforce treatments applied: automatic mode of the hydraulic downforce mechanism (AUTO) at 120 pounds pressure, and three additional manual downforce treatments at 125, 250, and 375 pounds pressure.

Figure 1 shows the differences in seeding depth with respect to different downforces evaluated. Data show that in sandy clay loam conditions, seeding depth increased as the downforce increased. But on sandy loam soil, there were no seeding depth differences except for the highest downforce (375 pounds) treatment.

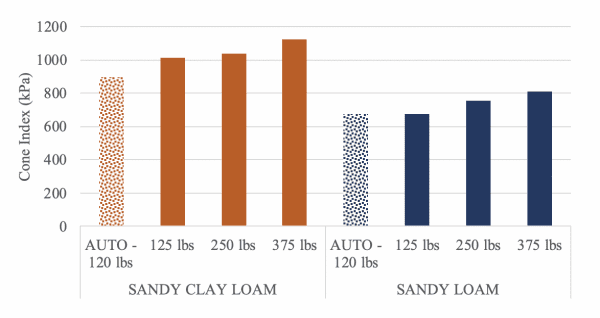

The impact of planter downforce on soil compaction was also measured. Figure 2 shows that soil compaction increased as the downforce (planter vertical load) increased, and the impact on soil compaction was higher on sandy clay loam soil. These results clearly suggest the need for finding a proper balance of planter downforce, seeding depth, and soil type to reduce impacts on soil properties.

Figure 2. Differences in soil cone index (a measure of soil compactness) as influenced by planter downforce and soil type. Downforce treatments applied: automatic mode of the hydraulic downforce mechanism (AUTO) at 120 pounds pressure, and three additional manual downforce treatments at 125, 250, and 375 pounds pressure.

Additional studies need to be conducted to fine-tune downforces by soil type that reduce soil compaction and place the seed at the appropriate soil depth. It is also necessary to determine the soil compaction level that might reduce corn germination and growth. The new precision planting technologies on the market today could certainly optimize planting operations. Their benefits are being evaluated, and farmers are being trained on their proper use.

Acknowledgments: Greg Pate, Director of the E. V. Smith Research Center, and Kris Balkcom, Extension Peanut Specialist, who provided significant support for this preliminary study. Vantage South, the Precision Planting Technologies dealer for Alabama, also provided support.