Crop Production

Tomatoes are the most widely produced greenhouse crop in the world. A large percentage of fresh-market tomatoes are grown in Canada and Mexico, and the United States is slowly building a market presence.

As with any business, profitability is the driving factor for this type of venture. Larger greenhouse facilities are typically better able to earn a profit due to volume produced and more efficient labor. Enterprises located near urban areas where direct-market customers are more willing to pay a premium also tend to be more profitable. Small facilities of one to two greenhouses struggle to profit with direct market sales. The most limiting factors to profitability in Alabama are winter heating costs and labor.

Another factor that affects profitability is the type of tomato grown. Greenhouse tomatoes are grown vertically on a trellis system to maximize space, and most are indeterminate tomato varieties, meaning they continue to grow after setting fruit. Conventional field- growing operations grow determinate tomato varieties that stop growing once fruiting has occurred. Growing indeterminate varieties helps spread the cost of starting a crop over an extended period of time, thus lowering the cost of startup.

Greenhouse tomato production consists of several stages and requires some decision making and planning up front. Some considerations include

the crop cycle to use, the seed variety to plant, the growing and support system to use, plant spacing and training methods, and fruit thinning, pollinating, irrigating, and fertilizing.

Crop Cycle

Greenhouses allow for year-round production of many crops; however, summer temperatures in southern states, including Alabama, can inhibit tomato production by reducing fruit quality and yield. Plants stressed by extreme heat are also more susceptible to pest damage. For these reasons, greenhouse tomatoes are only sometimes grown in standard greenhouses during the summer months. In other areas of the country, evaporative cooling can significantly reduce greenhouse temperatures, but this technology is limited in the highly humid southern United States.

Two crop-scheduling options are available for the extreme summer temperatures in the greenhouse. The first is a single, 10-month crop that is started in August and finished the following June. The second is the two- crop method, developed by Mississippi State University, which can produce similar yields during the same time span. The two-crop system also begins with an August planting date, but the first crop ends in December when a second crop is immediately transplanted for spring. The new, young crop is better able to handle the disease pressure associated with January and February, when ventilation rates are reduced and humidity remains high for extended periods.

Temperature

Tomatoes are a warm-season annual plant. Significant growth and yield can be achieved when daytime temperatures are maintained between 80 and 85 degrees F. Low temperatures damage tomato tissue. One sign of cold damage in tomato plants is leaves that turn purple and curl inward. In greenhouse tomato production where tomatoes are grown in the off season, adequate temperature is important, particularly during periods of cold weather. Therefore, growers should maintain nighttime temperatures between 65 and 60 degrees F but no lower.

In Alabama, growers more often have to deal with temperatures that are too high rather than too low. Excessively high temperatures can affect fruit development, resulting in cracked fruit and reduced fruit set. Shading during the warmer months can help reduce temperatures inside the greenhouse. Shading reduces light levels, which decreases photosynthesis and therefore yield; however, any reduction in yield due to shading is less than that caused by excessive heat. Shade cloths of 30 to 50 percent are common grades used with greenhouse vegetables. For more information about evaporative cooling, visit the Alabama Extension website at www.aces.edu.

Seedling Production

The first step in growing greenhouse tomatoes is to plant seeds. Start tomato seeds in 36-, 50-, or 72-cell nursery trays using a peat-based potting mix or in 1-inch block media, such as oasis cubes or Rockwool, and later transplant them into larger cells. Irrigate seedlings using clear water until the first true leaves appear. Once true leaves appear, switch plants to 50 parts per million (ppm) nitrogen. If using a 20-20-20 or 20-10-20 soluble fertilizer, 50 ppm of nitrogen will equal about 1 gram per gallon of water. Allow the media to dry slightly between waterings to encourage the roots to grow throughout the growing mix. Overwatered tomato transplants tend to grow tall and have thin, weak stems and poor root systems. Transplant seedlings when they are 4 to 6 inches high. Since warmer temperatures speed germination and seedling growth, use greenhouse- grade heating mats to supplement heat when needed to maintain a rootzone temperature of 84 degrees F. Most transplants can be produced in 4 to 6 weeks, depending on temperatures.

When choosing varieties, select those that are adapted to greenhouse conditions. Greenhouse tomatoes are typically labeled as such in commercial seed catalogs. These varieties are bred to be disease resistant and better able to tolerate low winter light conditions.

Growing Systems

Substrate-based systems are often used in greenhouse tomato production because large, vining plants need adequate root support that traditional hydroponic systems cannot provide. The three main substrates used in greenhouse production are perlite, pine bark, and Rockwool. Perlite and pine bark are used with container systems in which containers are placed on the greenhouse floor and the plants are trained up a wire or trellis throughout the growing cycle. The three types of containers commonly used in greenhouse production are the Dutch bucket, bag culture, and nursery pots. A Dutch bucket is a rectangular, 11-liter bucket that has a drainage hole. Bag culture uses a flexible plastic bag with drainage holes cut into its underside. Perlite works best in bag culture, but pine bark can also be used. Nursery pots are 3- or 5-gallon plastic pots used in ornamental production.

Rockwool, the other greenhouse substrate, is not used in container systems but is commonly used in highwire tomato-growing systems, typically in advanced greenhouses in cooler regions. Trellis wires are suspended at least 12 feet off the ground, as opposed to 6 to 8 feet in traditional greenhouses. Rockwool slabs are used in these taller systems to anchor roots and provide adequate moisture as plants can reach much larger sizes with the added vertical growing space. These large slabs or cubes have a high water- holding capacity and are often set on plastic troughs in production systems where the nutrients can drain. Smaller Rockwool cubes are used for transplant production. Rockwool is recommended for greenhouse production instead of soil because soil-based systems have a higher risk of bacterial infection from soil-borne diseases.

- Figure 1a. Three-gallon nursery pots filled with aged pine bark.

- Figure 1b. Dutch buckets filled with perlite.

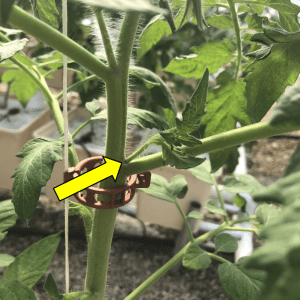

- Figure 2. Tomato clip secures main stem to twine.

- Figure 3. Sucker growth between main stem and leaf.

Plant Spacing and Training

Space tomato plants so that each has 3.5 to 5 square feet of growing area. Spacing should result in 16 inches of in-row spacing between plants and 5 feet of spacing between rows. A 30- by 96-foot greenhouse can accommodate five double rows of tomato plants. Typically, each growing container has two transplants, and each transplant is trained to one of two steel cables used as a trellis. These cables are suspended 8 to 10 feet above the crop, run the greenhouse length, and are 24 inches apart within each row. To train the plants, suspend strings from the cables and wrap the string around the growing point as the plant grows, or use plastic tomato clips every 10 inches along the plant’s main stem as shown in figure 2.

To maintain a single leader and distribute energy to fruit production instead of secondary vegetative growth, remove all suckers (secondary shoots that will form into a branch if left to grow) as they form. If left to grow, secondary growth will make vertical training difficult and interfere with airflow and light penetration into the canopy. Remove suckers when they are small and at least once a week. Remove the terminal bud at the overhead wire six weeks before the end of the crop cycle. Fruit will continue to develop and ripen along the main stem until the production cycle is finished.

Leaning

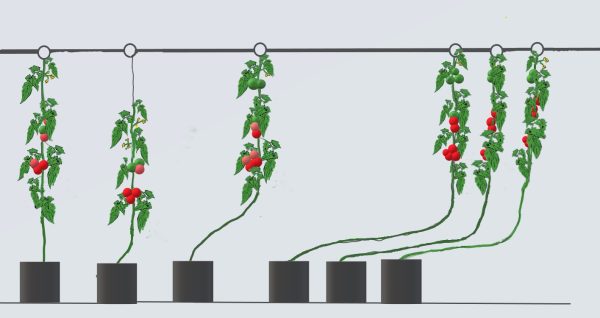

Figure 4. Progression of tomato leaning. As plants grow towards the wire from left to right, they are lowered, and the spool hangers are moved down the trellis wire to accommodate the additional growth.

One of the more common training methods used in greenhouse tomato growing is called leaning. The string or twine that tomato plants are attached to is typically wrapped around a spool that is hung from the trellis cable so that the plants can be lowered when they reach the trellis cable. As plants are lowered, the spools are simultaneously moved along the trellis cable, away from the base of the plant. As shown in figure 4, the vines eventually end up in an L shape, with a large portion of the vine running horizontally above the floor before extending upward toward the trellis cable. The horizontal portion of the vines should be suspended above the floor. Within the double row, the second row is trained in the opposite direction. When vines reach the end of the row, they are looped around to join the opposite row. Vines can grow more than 20 feet in one season; however, only the vertical portion of the vine will have leaves and fruit. Leaves and spent fruit clusters are pruned when knee or waist high, depending on the system. Maintaining 5 to 6 feet of leaves on the vine is important to provide energy for fruit production. Leaning allows the fruiting time to be extended without restarting the crop. Leaning and leaf pruning is done once a week as needed.

Support Systems

It is essential to use a well-designed support system for the tomato trellis. Do not use the greenhouse structure for support unless it was specifically designed to handle the weight; otherwise, structural damage may occur. Recommendations for support system designs can be found in the Mississippi State University “Greenhouse Tomato Handbook.”

- Figure 5a. Wooden structures hold steel cables for trellising twine to support tomato growth in a standard greenhouse.

- Figure 5b. Metal structures hold steel cables for trellising twine to support tomato growth in a standard greenhouse.

Fruit Thinning

Thin fruit once a week to maintain uniform size and shape of fruits. Thin clusters of the larger, slicing varieties to 4 to 5 fruits per cluster. For cherry and grape tomato varieties, do not thin unless the entire clusters are going to be harvested at one time. In this case, limiting clusters to 8 to 10 fruits can provide more uniform and faster ripening of the entire cluster. When thinning, remove any cracked, deformed, or damaged fruit first, followed by the smallest tomatoes on the cluster.

Pollination

Tomato flowers are perfect flowers, meaning they have male and female reproductive parts on the same flower and can self-pollinate. Cross-pollination, however, can result in better fruit set and yield. Because elevated temperatures and high humidity decrease pollination, it is best to pollinate during the middle of the day before it gets too hot and when the humidity is between 60 and 70 percent.

There are several effective pollination options for greenhouse tomatoes, including bumblebees, mechanical pollinators, and electric pollinators. Bumblebees are natural pollinators, but they require extra attention and a strong integrated pest management (IPM) program since pesticide use can disrupt bee activity. Bumblebees are typically used in larger greenhouse operations where there are enough flowers to support the population. Hives (or boxes) are sold based on coverage area. For example, a hive might be rated to support 1,000 to 5,000 square feet of greenhouse space, and boxes are active from 6 to 8 weeks before they need to be replaced.

Although there is a higher labor input, mechanical pollination can be used for smaller operations or early in the cropping season when there are not enough flowers to support bumblebee pollination. Other options are electric pollinators that vibrate the flower truss to release pollen, and leaf blowers can be used to simulate wind pollination in outdoor production; however, this is the least effective method. Pollinate plants three times a week as new flowers develop.

Fertilization and Irrigation

All nutrients are supplied through the irrigation system using drip tubes and emitters in greenhouse tomato production. Because tomatoes are a fruiting crop, they require higher levels of nutrition than other crops. Water quality affects how plants take up nutrients and should be monitored throughout the growing season. Electrical conductivity (EC) and pH should be maintained at 2. 0 to 2. 5 millisiemens per centimeter (mS/cm) and 5. 5 to 6. 5, respectively. Rather than using a single fertilizer containing all essential plant nutrients, commercial operations use two different fertilizer stock solutions that are injected into the irrigation line separately.

- Figure 6. Fertilizer injection system.

- Figure 7a. Drip irrigation in dutch bucket production.

- Figure 7b. Close-up of drip emitter.

One stock solution is a general fertilizer; the second is made up of calcium nitrate. Fertilizers are injected separately to prevent calcium phosphate from forming into a solid when high concentrations of calcium and phosphorus are in solution together. Growers can mix their own fertilizers or purchase premade products. There are some savings associated with formulating your own fertilizer; however, premade commercial products are recommended to reduce the risk of miscalculations and to save valuable time by eliminating the need to mix. For detailed instructions for formulating your own hydroponic fertilizer, refer to “Nutrient Solutions Formulations for Hydroponics” in the References and Suggested Reading section and the Mississippi State University “Greenhouse Tomato Handbook.”

Optimal nutrient concentrations depend on the growth stage of the plant. Table 1 lists ideal tomato nutrition for developing a regimen for greenhouse tomato production.

Along with proper fertilization, tomatoes require a large amount of water for proper growth. A general rule of thumb is to irrigate with enough water to saturate the growing media and provide 10 to 25 percent leachate from the pot. Irrigate throughout the daytime hours when plants are using water readily for photosynthesis. Irrigation volume depends on plant age and growing temperature; however, a general rule of thumb is that tomato plants receive 2 quarts of water per plant per day. Younger tomato plants do not need as much water as older plants, and plants need more water on hot, sunny days than on cloudy days. It is common for tomato plants to have frequent but short irrigation run times. This could mean more than 12 run times per day for mature crops.

Table 1. Sufficiency Ranges for Tomato Tissue and Nutrient Concentrations

Adapted from Mills and Jones 1996. Hochmuth and Hochmuth, 2018

| Macronurients | Tissue Sufficiency Ranges | Nutrient Solution Concentration Ranges (ppm) |

|---|---|---|

| Nitrogen | 3.5–5.0% | 70–150 |

| Phosphorus | 0.7–1.3% | 50 |

| Potassium | 1.0–6.0% | 120–200 |

| Calcium | 1.4–2.2% | 150 |

| Magnesium | 0.3–0.7% | 40-50 |

| Sulfur | 0.25–0.55% | 50–60 |

| Iron | 60–300 ppm | 2.8 |

| Manganese | 50–250 ppm | 0.8 |

| Boron | 25–75 ppm | 0.7 |

| Copper | 5–50 ppm | 0.2 |

| Zinc | 20–250 ppm | 0.3 |

| Molybdenum | 0.11–0.26 ppm | 0.05 |

Harvesting and Storage

Harvest greenhouse tomatoes at maturity or once they start to turn color. Harvest vine-ripened fruit at maturity when the fruit is fully red. Depending on the season, harvest 1 to 3 times a week. During cooler months, tomatoes can be harvested less frequently. As temperatures increase, tomatoes develop faster, and fruit harvest becomes frequent again. Frequent harvesting ensures that fruit is not left to overripen on the vine.

To harvest individual fruit, leave the calyx on to preserve freshness. Individual fruit can be harvested before fully ripe to prevent bruising during packaging and transporting. To harvest on-the-vine fruit, clip the whole cluster as it comes off the main stem. On -the-vine tomatoes are packed in a single layer in boxes or in trays. Slicing tomatoes for the commercial market are packed by weight in 25- to 30- pound cardboard boxes. Post-harvest storage temperature depends on the maturity of the harvested fruit. Generally, tomatoes can be stored at 50 to 55 degrees F for 2 to 3 weeks. Since tomatoes produce ethylene as they ripen, they should not be stored next to sensitive crops.

References and Suggested Reading

- Buonassisi, A. J. , Sabaratnam, S. , Woodske, D. , & Bitterlich, I. (2013). Biosecurity Guidelines for Post- harvest Greenhouse Tomatoes: Prevention of Post-harvest and Storage Rot.

- Hochmuth, G. J. (2012). Production of Greenhouse Tomatoes. In Florida Greenhouse Vegetable Production Handbook (Vol. 3). https://edis. ifas. ufl. edu/publication/CV266#TOP

- Hochmuth, G. J. , & Hochmuth, R. C. (2018). Nutrient Solution Formulation for Hydroponic (Perlite, Rockwool, NFT) Tomatoes in Florida. IFAS Extension Publication No. HS796. http://edis. ifas. ufl. edu.

- Mills, H. A. and Jones Jr. , J. B. (1996) Plant Analysis Handbook II. A Practical Sampling, Preparation, Analysis, and Interpretation Guide. Micro-Macro Publishing, Athens.

- Snyder, R. G. (2016). Greenhouse Tomato Handbook. Mississippi State University Extension Publication P1828.

- Rutledge, A. D. (1998). Commercial Greenhouse Tomato Production PB 1609. University of Tennessee Agricultural Extension Service.

Caroline Blanchard, Research Associate; Jeremy Pickens, Assistant Extension Professor; Andre da Silva, Extension Specialist, Assistant Professor; and Daniel Wells, Associate Professor, all in Horticulture with Auburn University

Caroline Blanchard, Research Associate; Jeremy Pickens, Assistant Extension Professor; Andre da Silva, Extension Specialist, Assistant Professor; and Daniel Wells, Associate Professor, all in Horticulture with Auburn University

New January 2023, Greenhouse Tomato Production, ANR-2955