Sheep & Goats

This is an excerpt of Dairy Goat and Sheep Operations in the Southeast Production Guide, ANR-2457.

Goat and Sheep Facilities

While shelters and fences are primary components of facilities, there are additional features to consider, such as feeders, water vessels, working stations, and other equipment. Management practices are more easily accomplished by drafting a comprehensive management plan on paper or computer. Basic factors to consider include the following:

- number of animals to be housed in each location with adequate space

- ability for goats/sheep to move about within areas

- animal/human/equipment accessibility to and from pastures, including pasture rotation

- ease of providing feed, water, and hay

- vermin-free and dry storage of hay and feed

- ability to isolate or separate animals as necessary, including pens for birthing and nursing

- ability to house animals based on gender, age, attitudes, and aggressiveness

- protection from wind, precipitation, and continuous sun exposure

- owner’s ability to maintain sanitary conditions

Facility Site and Design

It is important to consider structural costs, materials, accessibility (for people and animals), and functionality when designing, developing, or contracting a facility. Fencing and shelter should

be your primary concerns when determining appropriate facilities for goat/sheep production. Feeders, water vessels, and service equipment will be secondary.

Prior to establishing fencing, barns, and shelters, you should acquire an aerial map of the property and draft plans on paper or computer that account for the following:

- topography of land

- movement of water (streams and heavy rains)

- strategic placement for gate access and ease of movement for animals

- equipment

- future fencing

The state office of the United States Department of Agriculture’s Natural Resource and Conservation Service can provide assistance in the development of this plan.

Shelters or housing for goats/sheep can be as basic or elaborate as the designer intends. Some farmers have been able to modify former poultry houses or hog parlors into facilities for goats/sheep (figure 1). A semi-enclosed structure may be practical in areas where climates are mild to semi-tropical (figure 2). A well-enclosed structure will be necessary in colder climates.

Keep in mind that the primary purpose of shelter is to minimize stress from extreme environmental conditions (excessive precipitation, high or low temperatures, strong winds, and direct sunlight). Shelters also function as protection from predators, as a nursery during kidding season, and as storage for other relevant items, such as hay, feed, medicines, and tools.

- Figure 1. Former poultry house converted into facility to house goats; note kidding pens on left

- Figure 2. Semi-enclosed barn with potential for additions and modifications (Photo by Sydne and Robert Spencer, Spencer’s Farm)

Adequate Space

Adequate space is important to minimize infighting among animals. While head butting is a common method of establishing dominance, infighting may result in blows to the abdomen or backs of pregnant does, resulting in injuries to the fetus, abortions, or miscarriages. Each adult animal needs 15 to 30 square feet to move about at leisure; the footage is less for younger animals. Feeding space should allow for 12 to 18 linear inches of head and body space per animal.

Shelter Types

Premanufactured shelters come in various forms including small large calf hutches that can be readily purchased (figure 3). Small premanufactured shelters have enough space to house only a few animals. They function more like portable pens.

Larger hutches have the capacity to hold about ten adult goats/ sheep and come with side feeder doors, a top air vent, front feeder, a water holder, and other features.

Lengths of metal culvert with sufficient height (3 to 4 feet or more), such as those used in large drainage ditches, can be positioned to serve as housing. There are other objects, such as large commercial fertilizer or chemical vats, that, once sanitized, can be converted into housing. Some modification may be required, such as inverting the container, cutting in doors and windows for ventilation, and installing lights.

Portable shelters should always be considered a viable option, especially when a farm utilizes small paddocks for rotational grazing. These shelters also vary in size depending on availability and ability of equipment to move structures as needed.

Permanent shelters are every farmer’s dream, but budget constraints may place limitations on such dreams. Keep in mind that no matter what type of shelter is built, the structure should have sufficient space, ease of movement, durability, and adequate protection from the elements.

Separate Housing

At times, males, females, expectant or new mothers, and young or sick animals may require separate housing (figure 4). Males may need separate paddocks and housing for isolation from young and mature females during the nonbreeding season. Such areas and facilities should be situated at least several hundred yards away from areas where females are housed. Housing and fencing should also be properly maintained to contain bucks that tend to try to escape. Experienced producers are well aware of the challenges associated with containing an eager herd sire.

- Figure 3. Premanufactured goat hutch (Photo by Pat and Ken Motes, Clear Creek Farm)

- Figure 4. This structure is on skids and can be towed to another site using a tractor. (Photo by Sydne and Robert Spencer, Spencer’s Farm)

Shelter Flooring

Concrete, soil, and gravel serve as practical types of flooring, but function, needs, and affordability will be the determining factors for each structure. Concrete may be desirable and easy to clean with the proper equipment, but the initial coat may be prohibitive. Concrete flooring also requires slightly slopped flooring to allow for drainage of urine and excess water.

Soil and gravel-type flooring are generally affordable and practical. The only time they are impractical is when the stocking rate of animals is excessive and adequate drainage is nonexistent. Slotted flooring and wood are impractical and unsanitary.

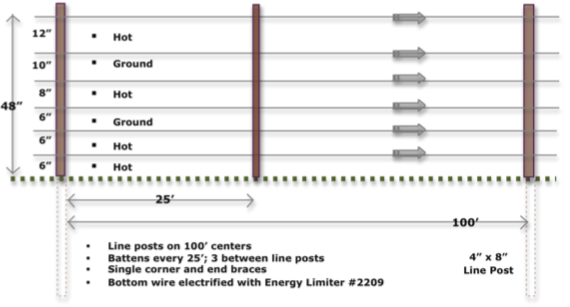

Figure 5. Fencing plan

Fencing

Perimeter fencing is highly important, as it contains your farm animals and serves as a barrier to other livestock, predators, and nuisance animals (neighborhood and stray dogs). The best fencing plan includes a combination of woven wire in conjunction with electric wire that is strategically placed along the exterior, interior, and top (figure 5). These features will keep your animals away from inside fencing where they may rub along the fence, scratch their sides and back, and stretch. This combination of fencing will also deter predators or nuisance animals from trying to climb or crawl over or dig under a fence.

A fence charger that provides five to six joules of shock is essential to gaining the attention of goats and sheep. Three ground rods 10 feet apart and 6 feet deep are essential to ensure sufficient ground during times of drought.

Fixed interior fencing or cross-fencing to facilitate rotational grazing and to separate animals is a long-term practice that offers a few options, such as the use of woven and fixed knot metal wire, poly wire, and high-tensile wire.

Equipment

Whatever feeder is used, it must be easy to maintain and sanitize. Prefabricated bunk feeders and hayracks can be purchased from any commercial feed store or equipment vendor. Given the opportunity, small ruminants will consume approximately 2 to 4 percent of their body weight in feed, forages, and hay.

A farmer may choose to construct his or her own feeder based on needs and facilities. A feed trough or insert made with plastic or PVC is generally practical and easy to clean (figure 6).

Figure 6. This feeder made on the farm from a 15-gallon plastic barrel cut in half is practical, affordable, and easy to clean. (Photo by Sydne and Robert Spencer, Spencer’s Farm)

Feeders made out of wood are impractical, since wood is porous, unsanitary, and holds bacteria that cause disease. Also, never leave grain-based feeds on the ground, since this practice may cause animals to ingest gastrointestinal parasites. Feed and water vessels that become contaminated with feces will also expose animals to similar problems. Hayracks should be designed to keep hay off the ground.

Water vessels come in metal, plastic, or rubber; they do require regular cleaning for sanitation purposes. The size of the water vessel will depend on the number of animals drinking from it; each animal will readily consume 2 to 4 percent of its body weight. The vessel must be accessible to young and adult animals, but it should not be where the young can easily climb into it and drown because they are unable to escape.

Depending on the time of year and other farm concerns, cleaning vessels on a regular basis is essential in order to provide clean water. An accessory such as an automatic float valve attached to a running hose or pipe will ensure an ever-present supply of water.

Summary

Goats and sheep will tolerate moderate amounts of inclement weather, but they have their limits. They will seek shelter appropriate to the weather conditions. Facility design and the ability to clean and maintain these facilities greatly impacts herd health. Ease of function, access, and use is important for regular maintenance and sanitation practices.

Animal behavior and reaction should also be considered when designing facilities. Animals have a herd mentality and flight instinct; safety for handler and animals should be a priority.

When designing a facility, it is wise to plan for the unexpected, for variables, and for future expansion; but keep it practical, affordable, and expandable.

Nutrient Management

Dairy goat and sheep production, like all other aspects of animal agriculture, makes use of available feed resources to produce a consumable product. Production of milk and other products, however, is not 100 percent efficient. There are always waste products, such as manure, bedding, mortalities, etc.

It is important to follow all applicable rules regarding the storage and use of animal manure. Contact the state environmental regulatory authority for details. Facility design information is available from the Natural Resource Conservation Service (NRCS- USDA). Nutrient application rates are available from the Alabama Cooperative Extension System at www.aces.edu.

There are two basic types of production: intensive and extensive. Intensive production is high input (capital, management, facilities) and requires high output for sustainability. For dairy goats and sheep, this type of production is characterized by minimal grazing/ pasture use, with most nutrient needs provided by harvested forages and concentrates.

Extensive production is a lower-input production requiring lower output for sustainability. Naturally occurring feedstuff is used and supplemented as needed with concentrates and harvested forages. An extensive goat or sheep dairy will have few buildings for the animals, allowing them to graze and forage when not being milked.

From an environmental standpoint, an intensive goat/sheep dairy with the animals housed in buildings will fit the classification of an animal feeding operation (AFO). Under some circumstances, it can be a concentrated animal feeding operation (CAFO). The extensive operation can fit under the AFO designation, but is less likely.

In intensive production, manure and other waste materials can build up as dry or liquid products and must be removed from the buildings, handled, and stored. Ultimately, the material must be put to use.

Manure management in an extensive operation is usually taken care of by forage/pasture management. Little manure is allowed to accumulate, as it is spread through foraging and grazing. Only when the animals are in the milking parlor does manure become a potential issue.

Nutrient management for an extensive operation is an integral part of pasture management, since the animals spread manure as they graze/browse. Intensive production, even if only an AFO, should have a plan for making use of the manure and other wastes.

It is the responsibility of everyone to protect our limited land and water resources. Making sure the environmental impact is neutral or positive requires thought and planning. The first step is identifying the potential risks for a farm. Such risks can include a creek, river, or stream on the property, a high water table, drainage ditches, and surrounding residences or public buildings.

Identifying potential risks allows for the development of a plan to minimize problems during operation. Avoiding or minimizing environ- mental risks is necessary for successful production.

Guidelines

- Apply manure based on soil test recommendations. Maintain pastures in a manner that avoids exposed soil. Do not overgraze!

- For pasture-based dairy goat/sheep production, a pasture plan is tops on the list of essentials from an environmental standpoint.

- For manure application, even an AFO should have documented nutrient management plans and records.

- Records should cover all aspects of manure production and use, even if most animals are maintained on pastures.

Summary

Good production records and practices are excellent tools for preventing problems and conflicts from arising. Considerations must be made for environmental stewardship if a dairy expects success.

Read more from the Dairy Goat and Sheep Operations in the Southeast Production Guide.

Download a PDF of Dairy Goat and Sheep Operations in the Southeast Production Guide, ANR-2457.