Forestry

Forestry best management practices minimize erosion on skid trails.

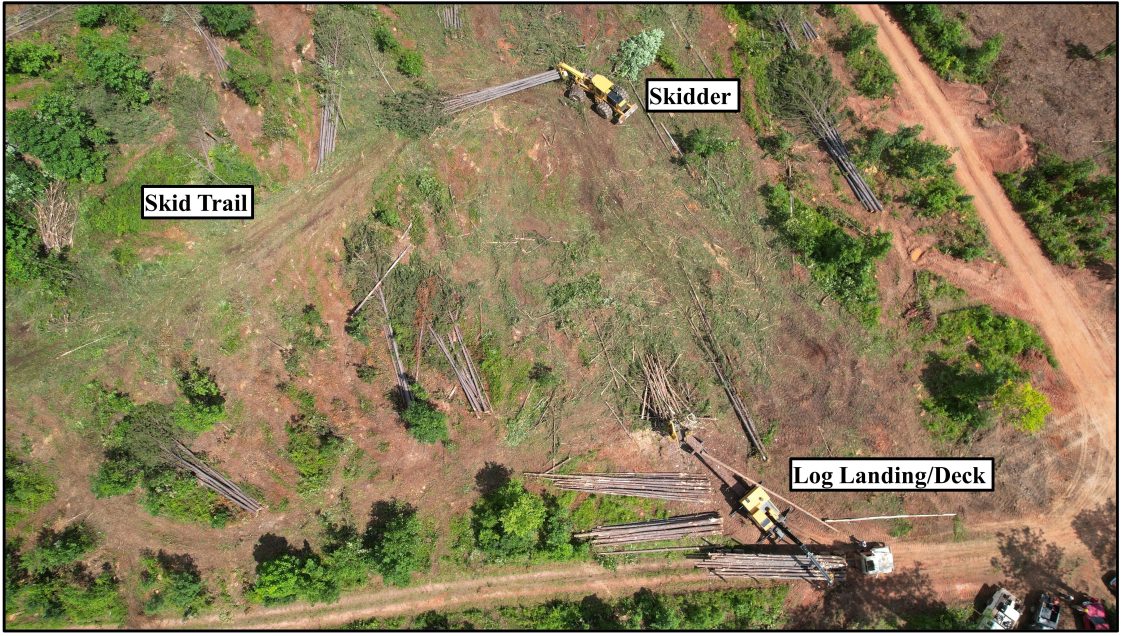

Figure 1. Skidder taking a grapple full of trees to the log landing/deck.

Skidders repeatedly skid or drag a grapple full of trees to a log landing or deck, where the loader operator processes the tree (delimbs and tops) and loads it on a log truck (figure 1). The trees in the skidder’s grapple are partially suspended but still have contact with the ground. Between the skidder’s weight, aggressive tires, and trees dragging on the ground, erosion can be a serious problem if the proper measures are not taken during and immediately following a timber harvest. Therefore, it is important for loggers to implement forestry best management practices (BMPs) on skid trails throughout the entire harvest area to minimize erosion. Furthermore, it is critical that BMPs are implemented on skid trail stream crossing approaches as these trails provide a direct route for erosion to reach a waterway. If eroded soil reaches a stream, it becomes sedimentation, which is a nonpoint source pollutant that can degrade water quality. Close-out BMPs need to be implemented before the logger moves off the harvest site (unless another crew is contracted to conduct BMP work).

There are two types of skid trails: bladed and overland (figure 2). Bladed skid trails are typically found in the mountains and involve excavating (blading) the soil to help the skidder traverse steep terrain while overland skid trails are used on flat and gentle terrain and do not involve any excavation of the soil. BMPs are critical for each type of skid trail since erosion can occur on both; however, bladed trails can result in much higher erosion rates.

Figure 2. Bladed and overland skid trails.

Skid Trail BMP Guidelines

- Plan main skid trail locations before harvesting (during harvest planning).

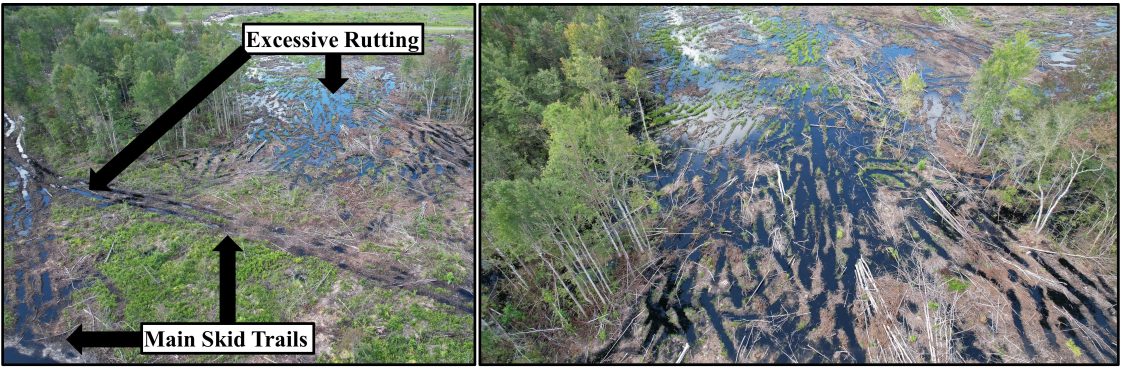

- Minimize rutting and compaction of the soil (figures 3 and 4).

- Use fewer skid trails on wet sites so rutting and soil compaction can easily be stabilized (avoid widespread skid trails) (figure 4).

- Drive on slash, logs, or wood mats to limit soil rutting and compaction (figures 5, 6, and 7).

- Do not use stream channels or natural drainages as skid trails, and do not skid within the streamside management zone (SMZ) unless crossing a stream (figure 8).

- Use proper stream-crossing methods.

- Locate skid trails along the slope contour where possible.

- If skid trails go up and down the slope, create breaks in the grade and not one long, continuous skid trail.

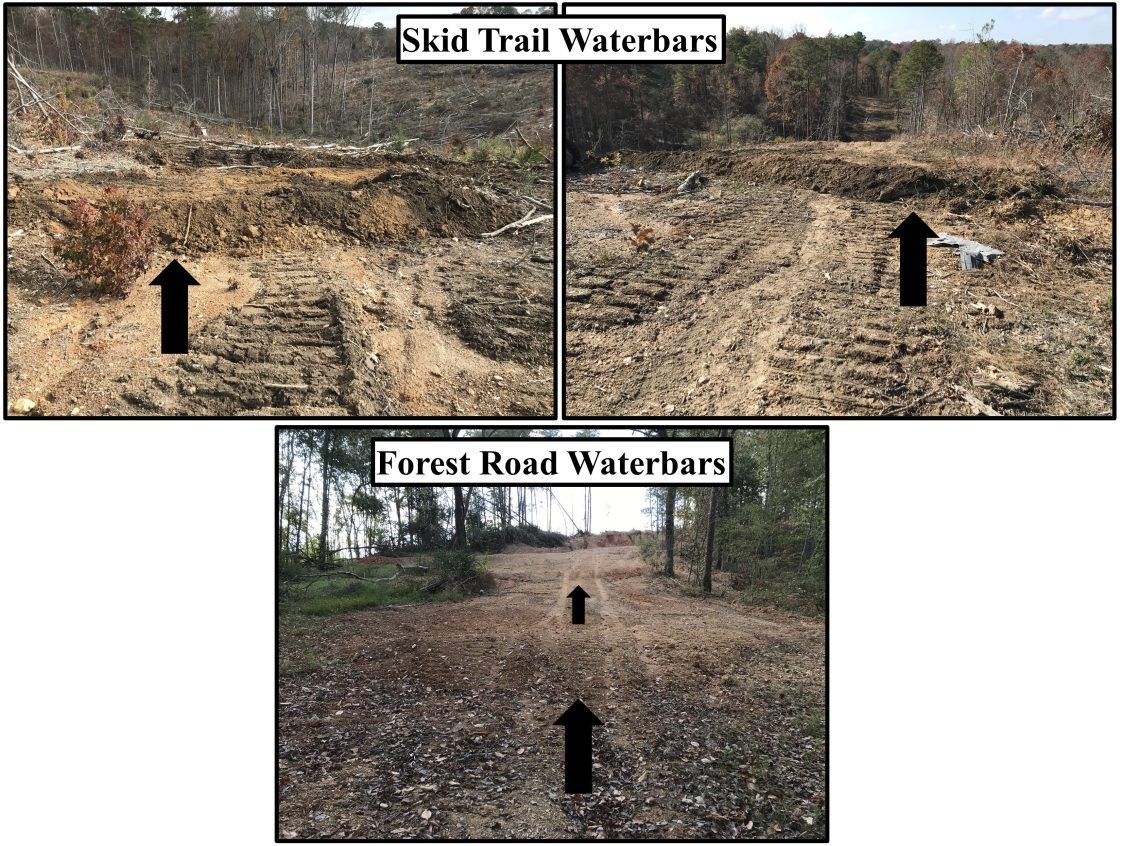

- Implement close-out BMPs to stabilize soil on skid trails (figure 9):

- (1) install water bars and turnouts (figure 10)

- (2) add grass seed and straw (figure 11)

- (3) scatter logging slash (figure 12)

- (4) use a combination of the above

- Help minimize soil rutting and compaction on wet sites by using dual tires, extra-wide tires, and tracks (figure 13).

Figure 3. Excessive rutting caused by a skidder. These types of ruts need to be avoided, and if they do occur, they should be fixed before leaving the site. Avoid deep rutting by waiting to harvest a tract or section of the tract when there has been significant rainfall (harvest during dry time of the year) or implement BMPs, such as placing logging slash or wood mats on the skid trail to skid over.

Figure 4. Excessive rutting on a wet tract and the rutting not fixed after completion of the timber harvest. See figures 3, 5, 6, and 7 for recommendations on how to avoid this issue.

Figure 5. Skidder taking slash from a gate delimber (left) and log landing/deck (right) and spreading it back across the site. This slash can be spread on skid trails for the skidder to drive over to minimize soil rutting and compaction like that seen in figures 3 and 4.

Figure 6. Skidder operator placed slash from the log landing/deck on the main skid trail to avoid soil rutting and compaction while harvesting during wet weather.

Figure 7. Wood mats work well to reduce soil rutting and compaction from forestry equipment.

Figure 8. The skid trail was too close to the drain. Keep skid trails out of the streamside management zone (SMZ) except when crossing a stream. There also were no close-out BMPs implemented. (Photo credit: Andrew Vinson, Virginia Department of Forestry)

Figure 9. Steep skid trail that went directly into a drain and had no close-out BMPs implemented. (Photo credit: Andrew Vinson, Virginia Department of Forestry)

Figure 10. Skid trail water bars (top) need to be installed on sloped sections of skid trails. It is critical to install them on stream crossing approaches. Skid trail water bars can be larger and wider than forest road water bars (bottom) since they do not have to be designed for vehicle passage.

Figure 11. Grass seed and straw (left) and grass seed and silt fence (right) implemented as a close-out BMP on skid trails to stabilize the soil. Silt fences help slow down runoff and erosion that, in turn, can help grass seed germination. (Photo credit: (left) Andrew Vinson, Virginia Department of Forestry and (right) North Carolina Forest Service)

Figure 12. Logging slash scattered over a skid trail to reduce erosion as a close-out BMP option.

Figure 13. Tracked (left) or dual tire (right) skidders reduce ground pressure and can help minimize soil rutting and compaction when harvesting on wet sites.

More Information on Skid Trail BMPs

Alabama’s Best Management Practices for Forestry

Alabama Forestry Commission

www.forestry.alabama.gov

“Timber Harvesting Guidelines for Forestry Best Management Practices”

Alabama Cooperative Extension System

www.aces.edu

Richard Cristan, Extension Specialist, Assistant Professor, Forestry, Wildlife and Environment, Auburn University. Carey Potter, BMP Coordinator, Alabama Forestry Commission.

Richard Cristan, Extension Specialist, Assistant Professor, Forestry, Wildlife and Environment, Auburn University. Carey Potter, BMP Coordinator, Alabama Forestry Commission.

New February 2024, Forestry Best Management Practices: Skid Trails, FOR-2153