Forestry

Wood is one of the most well-known construction materials for consumers. When people think of these materials, they often think of boards such as 2 x 4 s and plywood. However, there are many other wood materials that are used in construction. Engineered wood products and mass timber systems, like cross-laminated timber (CLT), are increasingly being used for mid and high-rise construction in the United States.

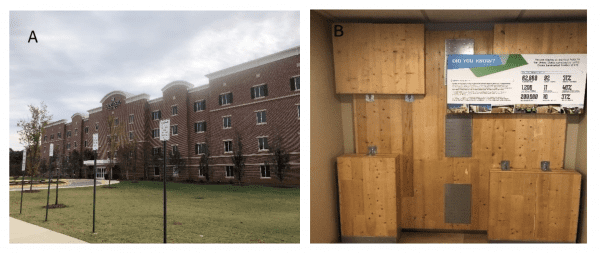

DID YOU KNOW? Mass timber is a category of construction material characterized by the use of large solid wood panels. CLT is a type of mass timber and the first hotel in the United States constructed of CLT is located at Redstone Arsenal in Huntsville, Alabama (Figure 2A and B).

What is CLT?

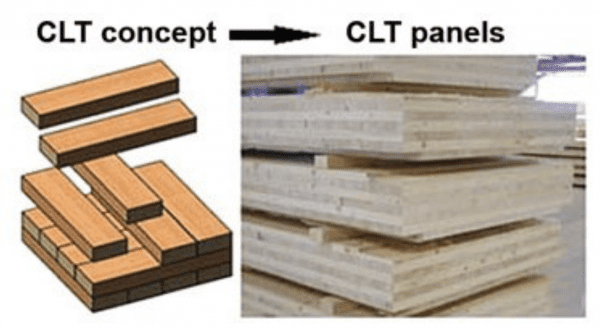

Figure 1. CLT design concept of using dimensional lumber to create multilayer wooden panels. Image Credit: USDA Forest Service, Forest Products Laboratory.

CLT is a prefabricated, engineered solid wood panel made of layers of dimensional lumber. The lumber is stacked crosswise at right angles, glued, and then pressed into place (Figure 1). The panels are then transported to the construction site where they are precisely connected using joints and structural adhesives. CLT originated in Europe in the 90s. It is now used around the world, including several locations in the US. The Southeast is a growing hotspot for mass timber production because of its large supply, historical production rates, and growing efficiency of Southern yellow pine timber.

Relevance to Alabama

Forest products are a critical part of Alabama’s economy. Alabama has a total land area of over 32 million acres, of which approximately 71 percent is considered productive timberland. Alabama ranks third in overall timberland in the contiguous US, leads the nation in loblolly pine growing stock (approximately 544 million tons), and it is estimated that roughly half of the standing timber in the state is of sawlog size (sawtimber) or larger. Sawtimber class timber is a source of raw material for producing CLT.

The manufacturing of CLT provides an opportunity to strengthen the state’s forestry industry. CLT production provides new market opportunities for Alabama producers, as sawtimber is raw material source used in CLT production. The use of mass-timber products is the future of sustainable building and Alabama timber producers currently serve an important role in the production in the Southeast. Since its origination, CLT is now used around the world, including several locations in the United States, including the Southeast.

Advantages of CLT

Because CLT is a relatively new material to architects, contractors, the forestry industry, and consumers in North America, extensive research and outreach education is currently being done. Through this research, several advantages of using CLT have already been determined.

- Environmental advantages. In addition to being energy efficiency, as a wood product, CLT has a smaller carbon footprint than steel and concrete. Even after being manufactured, wood products continue to store the carbon that was absorbed by the trees. CLT is also a more sustainable material than steel or concrete and produces a net reduction in atmospheric carbon dioxide and has a minimal waste production.

- Design flexibility. CLT can be used in walls, roofs, and floors. It is also relatively easy to increase its thickness to meet many specifications.

- Energy efficiency. CLT panels are thick and tightly jointed when constructed, resulting in less potential for passing airflow and requires less added insulation.

- Fire protection. Because of its thickness and cross-section design, CLT provides resistance to fire. The slow charring panels provide added protection from further deterioration, acting as a natural insulator protecting inner layers from flames.

- Seismic and wind performance. Continuing research has shown that CLT has excellent dimensional stability and rigidity. Research on seismic testing has found that CLT performs extremely well against collapse. Similarly, research shows that CLT performs extremely well against damaging winds. Both of these instances in-part are because of CLT’s structural flexibility which reduces the chances of break.

- Acoustic performance. Research shows that the mass of CLT panels and their airtight construction contributes to acoustic performance. This provides adequate noise control and limits airborne and impact sound transmissions.

- Construction efficiency. CLT is lighter than concrete is and faster to construct because of the prefabrication and preciseness of the panels.

- Aesthetics. Prefabrication of CLT acts as the inner skeleton of a building, therefore, specific external visual requirements are not an issue (Figure 2).

Figure 2a. The first hotel in the United States constructed using CLT and shelled for a specific appearance. Redstone Arsenal, Huntsville, Alabama. Figure 2b. CLT display at the hotel at the Redstone Arsenal. Demonstrating the design and construction of CLT.

Featured image by Thomas Robinson, founder and principal LEVER Architecture.