Forestry

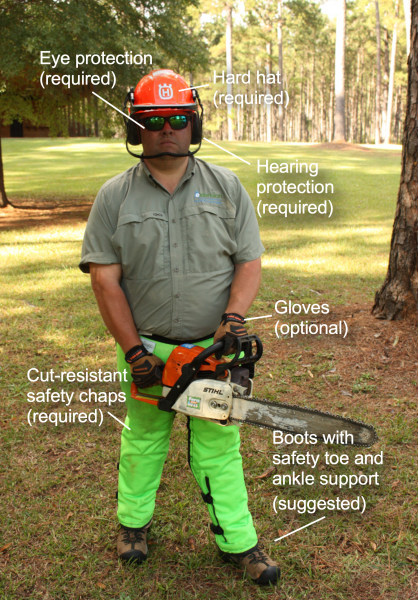

Figure 1. Personal protective equipment (PPE) that should be used when operating a chainsaw.

Whether an industry professional or homeowner that rarely uses a chainsaw, use of personal protective equipment when running a saw is essential. Proper PPE can significantly reduce the chances of a severe injury or even death.

More than 36,000 injuries associated with chainsaws happen every year in the United States. On average, these injuries require 110 stitches at a cost of $12,000 per injury before factoring in losses in production and time. In Alabama alone, state agencies have reported more than 70 chainsaw-related incidents over the past 5 years.

Personal protective equipment (PPE) worn while operating a chainsaw helps protect the areas of the body at greatest risk. The left leg, specifically upper thigh area, and the back of the left hand are the two areas most prone to injury. The head and upper torso are both at risk from falling debris and chainsaw injury from rotational kickback.

Essential PPE for chainsaw operation includes a hard hat, cut-resistant safety chaps, and eye and hearing protection (figure 1). The possibility of injury is so great that even those assisting the chainsaw operator should wear the full recommended protective equipment.

The left leg, specifically the upper thigh area, and the back of the left hand are the two areas most prone to injury.

Head Protection

A hard hat (figure 2) protects the head from falling debris, such as limbs and branches, and from injury due to hits against low-hanging objects. The shell of the hard hat is typically made of a high-density thermoplastic that is durable and resistant to falling debris and impacts.

What to Look for in a Hard Hat

A hard hat should have three components: shell, suspension, and chin strap (figure 3). These components must be properly functioning, free of damage or defects, and properly worn by the user. Do not drill ventilation holes into the shell of a hard hat that was not manufactured with them. Some hard hats are designed by manufacturers to have ventilation ports; however, there is some risk of small debris entering through these areas.

- Figure 2. Hard hats are an essential piece of PPE. Multiple styles are available.

- Figure 3. Essential components of a hard hat.

- Figure 4. A date of manufacture is stamped onto all hard hats.

Regularly Inspect Hard Hats

Inspect your hard hat before each use. Cracks or other physical damage can reduce effectiveness. Over time, excessive sunlight exposure, chemical exposure, and age can cause the shell to become brittle and unsafe. A simple method to test the elasticity of the hard hat is to push in on the exterior sides; the hat should compress inward and quickly expand to its original form. If this doesn’t happen, or if the hard hat begins to make a popping and cracking sound or develops a crack, replace it. Other warning signs of a damaged hard hat shell include fading color or chalky appearance. Also inspect the suspension straps for cut or frayed straps or damage to the connections to the shell.

When to Replace Hard Hats

Replace a hard hat 5 years after the stamped manufacture date, or sooner if it is damaged or experiences signs of wear as outlined above. All hard hats will come with the date of manufacture stamped inside (figure 4). This date is displayed by two dial-like symbols with an arrow inside pointing to a number. The first dial points to the month, and the number alongside the arrow designates a year. The second dial arrow points to a number specifying the date.

How to Wear a Hard Hat

Position your hard hat squarely on the top of your head, facing forward. Keep the space open between the hard hat shell and the suspension. Do not store items inside the hat or wear a baseball cap; this could cause a head injury when the hard hat compresses when struck by a falling object.

An often unused component of the hard hat is the chin strap. A hard hat will come either with the chin strap permanently attached or with slots for a chin strap attachment. Chin straps help secure the hard hat to your head in situations where you are leaning over, in high winds, or in an elevated area.

Leg Protection

Wear leg protection at all times when operating a chainsaw. The most common form of leg protection is cut-resistant safety chaps, commonly referred to as chainsaw chaps. It is important to understand that this style of chaps is not cut-proof; it does not eliminate all risks to legs but does reduce the potential for injury.

How Safety Chaps Work

Chainsaw safety chaps are composed of a rough exterior layer and an interior layer composed of long strands of nylon, polyester, Avertic, or Kevlar that extend the length of the chap. When a moving chain comes in contact with the chaps, it easily cuts the exterior layer while the inner strands pull out and tangle the drive sprocket. This quickly and effectively slows or completely stops the moving chain.

Types of Chaps

Chaps come in three styles: apron, calf wrap, and full wrap. Apron styles provide protection from the hips down to 2 inches past the top of the boot minimum on the front side of the leg only (figure 5). Calf-wrap chaps provide protection in the same areas as apron styles plus cover the entire calf (figure 6). Full-wrap chaps provide protection around the entire leg, including the calves and thighs.

Chaps are manufactured with a range of protective layers, or ply, which correlate to the size of chainsaw used. All chainsaw safety chaps should come from the manufacturer with an Underwriter Laboratories (UL) label verifying that the level of leg protection has been tested and meets the minimum cut resistance standards.

- Figure 5. Apron style safety chaps.

- Figure 6. Calf-wrap safety chaps.

- Figure 7. Chaps should extend to the top of the foot.

Selecting the Right Size Chaps

Chainsaw safety chaps are designed to be worn over clothes. Proper fit is essential to maximize the functionality of the chap. When purchasing a set of safety chaps, pay attention to the length of the chap and how it is measured. Some manufacturers use a standard pant inseam for sizing, while others provide the overall length of the chaps as a size reference.

Tips for Wearing Chaps

Chaps should fit snugly with all straps connected, not just the hip strap. If all the straps are not securely buckled, the moving chain could potentially pull the chaps out of the way, exposing your leg. Chaps should also extend down to the top of your foot (figure 7).

Chap Maintenance

Clean chaps according to manufacturer guidelines. This typically involves washing with a mild detergent and air drying. Never put them in the dryer; the cut-resistant material could be damaged. If chaps have been folded and stored, a good practice before use is to unfold and shake the pants; this helps the internal fibers to realign. Lastly, if the chaps are ever damaged and interior fabric is exposed, dispose of them. Never try to close the hole by sewing or patching.

Eye Protection

Wear safety glasses or goggles to prevent flying debris from entering your eyes. Eye protection should be impact resistant and offer protection on all sides.

Corrective glasses and sunglasses typically do not offer this type of protection and should not be worn in the place of safety glasses. If either of these types

of glasses is needed, wear a safety goggle over the outside of the glasses or a face shield to ensure proper eye protection.

Tip: Keep safety glasses clean and apply an anti-fog coating to reduce fogging and the temptation to remove and cut without glasses.

Some hard hats designed for chainsaw use may come equipped with a clear plastic or mesh face shield (figure 8). The clear plastic will suffice for eye protection, but safety glasses or goggles are considered better. The mesh face shield will help prevent large pieces of debris from getting into eyes but should not be used in place of safety glasses.

- Figure 8. Hard hat face shields can be clear plastic or mesh.

- Figure 9. Earplugs are inserted into the ear canal.

- Figure 10. Ear muffs should fit snuggly over the entire ear.

Hearing Protection

Gas-powered chainsaws operate at a sound level of 110 decibels, which will cause hearing damage if prolonged exposure occurs. To mitigate hearing damage, wear hearing protection whenever the saw is in operation. To ensure adequate hearing protection, noise should be reduced to below 85 decibels. Since most chainsaws operate at 110 decibels, or more, hearing protection should exceed a 25-decibel reduction. Two acceptable forms of hearing protection are earplugs and earmuffs.

Earplugs

Earplugs are manufactured out of a soft plastic or foam and designed to be inserted into the ear canal. Earplugs are typically the cheapest in cost and most effective in noise reduction, but they may not be the most comfortable to wear.

Tip: Earplugs must be used correctly to be effective. To properly insert earplugs, reach over your head with the arm opposite the ear being plugged. Pull up on the top of the ear to straighten the ear canal and insert the plug.

Earmuffs

Earmuffs are designed to fit snugly over the entire ear (figure 10). Noise reduction and hearing protection from earmuffs will vary depending on style. Some hard hats come equipped with earmuffs. To maximize hearing protection, they must cover the ears and fit snugly against the head.

In some situations, wearing both earplugs and earmuffs may be necessary. Wearing both does not increase sound reduction capacity but will increase the amount of hearing protection. The added protection is calculated as a 5-decibel increase of the higher level of protection. For example, if you are wearing earplugs that offer 33-decibel reduction and earmuffs that offer 25-decibel reduction, the level of protection will be 38 decibels (33 decibels plus 5).

Foot Protection

Figure 11. Gloves should be worn when performing saw maintenance.

Many cutting situations involve risk to feet and ankles, whether from missing the target or stumbling. Always wear heavy work boots or shoes with high ankle support when operating a chainsaw. Steel- or safety-toed boots will further protect your toes from being cut by the saw or crushed by heavy debris. Cut-resistant safety boots are commercially available but are not required; these types of boots provide the maximum amount of protection but can be extremely hot to wear.

Hand Protection

Although not required when operating a chainsaw, hand protection is recommended to protect hands from abrasions, cuts, and burns. Always wear gloves when performing saw maintenance or changing or sharpening a chain (figure 11); you are at greatest risk of being cut or burned in these situations. Gloves also can help you grip and control the saw better. Cut-resistant gloves are commercially available but are rigid and can make it difficult to operate a saw while wearing.

In addition to proper PPE, always wear clothing that is trim fitting and free of any ragged edges that could be entangled in the saw or snag on debris. If you are required to wear high-visibility safety vests, they should be the tear-away kind in case caught by the saw.

Bence Carter, Regional Extension Agent, and Arnold “Beau” Brodbeck, Extension Specialist, both in Forestry, Wildlife, & Natural Resources, Auburn University

Bence Carter, Regional Extension Agent, and Arnold “Beau” Brodbeck, Extension Specialist, both in Forestry, Wildlife, & Natural Resources, Auburn University

New September 2021, Chainsaw Safety: Personal Protective Equipment, FOR-2106