Farming

This information highlights the results of a two-year study (2017-2019) evaluating nutritive value and fermentation parameters of different cool-season annual mixtures for baleage production in Shorter, Alabama.

What is Baleage?

Baleage is a high-moisture feed used as an alternative to dry hay. When compared with dry hay, baleage allows for potentially greater forage quality when harvested by reducing the time needed to dry after cutting and allowing for more timely harvests.

Harvesting

Grasses should be cut at boot stage while legumes should be cut at 10 percent bloom. This ensures the plant is at the optimal maturity (vegetative stage) when harvested. Plants cut at optimal maturity will have the greatest nutrient content because the plant has not reached the reproductive stage when they use carbohydrate reserves to produce seeds for reproduction.

Baling at the proper moisture prevents excess spoilage and mold production. When baled correctly and at the proper moisture, microorganisms (mainly bacteria) will begin to ferment carbohydrates to lactic acid (LA). This prevents the growth and proliferation of harmful microbes by lowering the pH.

Why Evaluate Fermentation Characteristics?

Proper fermentation is vital to the nutritive quality of the forage mixtures. If poor fermentation occurs, there is an excess of dry matter loss, as well as mold and yeast production and butyric acid production – which corresponds to a clostridial fermentation. The poor fermentation will reduce feed quality and increase refusals from livestock.

What is Silage Inoculant?

Silage inoculants contain a variety of lactic acid bacteria. They are applied to aide and enhance the rate of forage fermentation, aerobic stability, and maintain nutrient quality when preserved as a high-moisture feedstuffs.

The introduced bacteria aim to increase the rate of fermentation and lower the pH faster, which decreases dry matter losses and produces acids that inhibit microbial growth of molds. Three types of inoculants are marketed: homofermentative, heterofermentative, and a combination of the two.

Homofermentative inoculant introduces lactic acid whereas heterofermentative introduces acetic acid. A combination inoculant introduces both lactic and acetic acid. These acids are key to decreasing the pH to prevent unwanted acid production. They also make the feedstuffs more stable at feed-out in the humid conditions of the Southeast.

Treatments

The following treatments were evaluated:

- Wheat + Crimson Clover (WC)

- Wheat + T-raptor (WT)

- Annual Ryegrass + Oats + Crimson Clover (ROC)

- Inoculated (I)

- Non-Inoculated (N)

Plots were harvested and wilted overnight in the lab to simulate drying time in the field. Each forage treatment had inoculant applied to half of the treatment and then were ensiled into mini silos constructed from PVC pipe. Samples were taken from silos at 0, 7, 14, 21, 28, 45, 60, and 120 days after ensiling (DAE). The samples were analyzed for nutritive value and fermentation parameters.

Results

Crude protein was greatest for the WC treatment but was not expected due to the T-raptor component. However, there was a lack of T-raptor in the mixture due to a lack of establishment. There was an inconsistency of crude protein for I and N treatments shown in Table 1.

Table 1. Crude Protein of Baleage from Cool-Season Annual Forage Mixtures

| Inoculant Treatment | Wheat + Clover Forage Treatment (%) | Wheat + T-Raptor Forage Treatment (%) | Ryegrass + Oats + Clover Forage Treatment (%) | Mean |

|---|---|---|---|---|

| Inoculated | 17.8 | 13.8 | 15.0 | 15.5 |

| Not Inoculated | 16.4 | 13.0 | 16.6 | 15.3 |

| Mean | 17.1 | 13.4 | 15.8 |

Fermentation can be characterized by the pH change over time. A rapid pH decline corresponds to proper acid production which decreases dry matter loses and reaches a stable state. Lactic acid should accumulate first which will decrease the pH and result in a stable feedstuff. Acetic acid will be produced after the fermentation process is completed and will allow the feedstuff to maintain stability once exposed to oxygen.

Table 2. pH of Baleage from Cool-Season Annual Forage Mixtures

| Days After Ensiling | Wheat + Clover Forage Treatment (%) | Wheat + T-Raptor Forage Treatment (%) | Ryegrass + Oats + Clover Forage Treatment (%) | Mean |

|---|---|---|---|---|

| 0 | 6.3 | 5.7 | 6.3 | 6.1 |

| 7 | 4.4 | 4.3 | 5.7 | 4.8 |

| 14 | 4.3 | 4.3 | 5.0 | 4.5 |

| 21 | 4.5 | 4.4 | 5.4 | 4.8 |

| 28 | 4.6 | 4.4 | 5.5 | 4.9 |

| 45 | 4.6 | 4.5 | 5.5 | 4.8 |

| 60 | 4.8 | 4.5 | 5.3 | 4.8 |

| 120 | 5.8 | 4.5 | 5.2 | 5.2 |

| Mean | 4.9 | 4.6 | 5.5 |

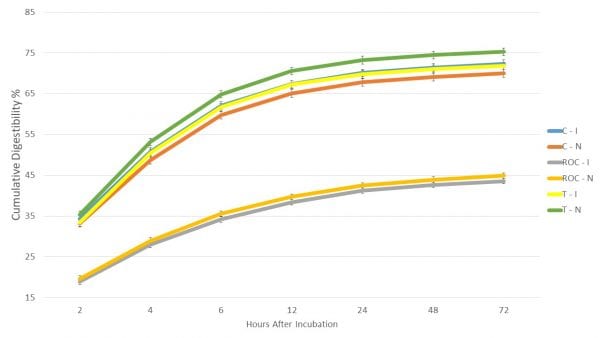

Figure 1. Cumulative digestibility of baleage from three cool-season annual forage mixtures with or without inoculant at 2, 4, 6, 12, 24, 48, and 72 hours after ruminal incubation.

Nutritive value in terms of crude protein was great enough for all forage treatments to sustain cattle at any stage of growth. However, there were differences in terms of fiber and digestibility fractions that could impact the value of the feed.

The ROC treatment had greater fiber content and resulted in lower cumulative digestibility. Acid production did not correspond with the hypothesis that non-inoculated treatments had greater lactic acid content and inoculated treatments had greater acetic acid content.

It was thought that there would be a greater concentration of both acids in the inoculated treatments. Again, ROC did not ensile well and never reached an appropriate pH level. This resulted in unwanted acid production that would result in refusal at the bunk, as well as decreased nutritive quality.

At this time, it is not recommended for producers to utilize a silage inoculant on cool-season annual forage mixtures because of the added cost of the inoculant with no benefits. However, the cool-season annual mixtures used are viable options for producers to utilize on a farm, as they are able to sustain growing cattle when managed properly.