Farming

Best practices in all aspects of poultry production was the subject of multiple workshops, trainings, social media posts, podcasts, and publications generated by Alabama Extension poultry specialists in 2023 for audiences ranging from industry professionals to keepers of backyard flocks.

Optimizing Feed Processing to Improve Animal Performance

Project Leader: Wilmer Pacheco

Project Leader: Wilmer Pacheco

Institutional Lead: 1862 Extension – AU

Project Objectives: Train industry personnel on good manufacturing practices, food safety plans, feed milling processes, and quality control of ingredients and finished feeds. Increase awareness of the role of feed mills in the animal feed value chain.

Background/Situation/Issue: Feed cost represents between 60 and 70 percent of the total animal production cost. Well-trained personnel can help to reduce inefficiencies in feed processing; this can contribute to higher profitability, lower nutrient excretion, and lower meat prices to the final consumers.

Social Media Channels: LinkedIn, YouTube, and Engormix

Outputs: Participated as guest and host of eleven podcasts in feed science (The Feed Science Podcast Show) and poultry (The Poultry Podcast Show). Podcasts were in Spanish and English and lasted approximately 400 minutes, receiving approximately 10,000 views in YouTube alone. A feed milling workshop was organized to train the feed industry in the southeastern United States. One article per month was published in Feedstuffs magazine, which is the leading source for news in agriculture, with more than 12,500 subscribers.

Audience Diversity: The feed mill workshop was attended by seventy-two people from twenty companies.

Value Statement/Synopsis: A trained workforce will help to increase the sustainability of the animal and feed industry in Alabama and the United States.

Revenue Generation: In general, 10 percent improvement in pellet quality can lead to an improvement in one point of feed efficiency, or savings of roughly $2 per ton of feed produced. By optimizing feed efficiency, we not only enhance animal performance but also reduce the ecological footprint associated with nutrient excretion and mitigate the potential environmental impact of animal production.

Commercial Poultry Basics

Project Leader: Wilmer Pacheco

Institutional Lead: 1862 Extension – AU

Co-leaders/Collaborators: Dianna Bourassa, Dennis Brothers, Brigid McCrea, Kent Stanford, and Rishi Prasad

Project Objectives: Provide training for new poultry industry professionals on the range of aspects that go into production of poultry products from farm to fork.

Background/Situation/Issue: Many poultry industry professionals lack the background training and knowledge of the multiple areas of expertise needed for production of poultry products.

Outputs: Participants in Commercial Poultry Basics training learn about the poultry industry history and structure, animal welfare, biosecurity, bird health, poultry genetics, breeder management, hatchery management, broiler management, layer management, turkey management, nutrition, processing, and how to work with people.

Audience Diversity: The 2023 Commercial Poultry Basics training served nineteen attendees (ten male and nine female) from seven companies that do business in the state of Alabama.

Evaluation Techniques: Online surveys were distributed post-training.

Value Statement/Synopsis: The poultry industry is facing employee shortages. This workshop can help employees with minimal poultry backgrounds to have a successful career regardless of their main area of production (live production [broiler, breeders, layers], processing, and/or further processing).

HACCP Roundtable

Project Leader: Dianna Bourassa

Institutional Lead: 1862 Extension – AU

Project Objectives: The Poultry Processors HACCP Roundtable discussion is a forum where processing and food safety personnel come together to discuss current food safety and regulatory issues facing the industry. Participants have the opportunity to address current concerns and assemble a list of food safety and regulatory questions. In the afternoon session, those questions are presented to USDA-FSIS personnel by the moderator.

Background/Situation/Issue: The processing of poultry is a heavily regulated process needed to supply the people of the United States and the world with safe and wholesome poultry meat for consumption. Respectful relationships between processors and regulators are needed in order to efficiently produce products while also addressing any potential problems.

Outputs: HACCP Roundtable meetings are conducted four times per year. Following each meeting, a summary of the questions and responses is distributed to all participants.

Evaluation Techniques: Each quarter, participants are verbally surveyed regarding what they do and do not like about the meetings and how future meetings can best serve their needs.

Value Statement/Synopsis: The HACCP Roundtable promotes effective communications between poultry processors and government regulators that will ultimately result in the production of safer food products for consumers.

Alabama Poultry Processor Meeting

Project Leader: Dianna Bourassa

Institutional Lead: 1862 Extension – AU

Project Objectives: Provide training for Alabama poultry processing professionals on regulatory compliance, troubleshooting common processing issues, and new methods for improving animal welfare, food safety, and meat quality during processing.

Background/Situation/Issue: There are eighteen commercial poultry processing facilities in Alabama that together process more than one billion chickens every year. Improvements in animal welfare, processing procedures, and food safety have significant impacts on the animals that are processed, the people employed in processing facilities, and consumers of chicken products.

Outputs: The first Alabama poultry processors meeting was held in 2023 with great success. The six invited speakers presented on multiple topics ranging from USDA-FSIS inspection decisions to primary processing factors impacting yields to facility sanitation.

Audience Diversity: The 2023 Alabama poultry processors meeting served twenty-seven attendees from ten companies that do business in the state of Alabama.

Evaluation Techniques: Online surveys were distributed post-training.

Value Statement/Synopsis: The Alabama Poultry Processors meeting provides continuing education for poultry processing personnel for the improvement in efficiency and safety of poultry meat.

WOGS (Worthwhile Operational Guidelines and Suggestions) Newsletter

Project Leader: Dianna Bourassa

Institutional Lead: 1862 Extension – AU

Project Objectives: Provide timely information to commercial poultry processors on topics ranging from harvest, bird welfare, meat quality, and system operations.

Outputs: Newsletters are distributed to subscribers involved in the commercial poultry processing industry. To date, there have been 221 newsletters on a diverse range of poultry processing topics.

Audience Diversity: The WOGS newsletter is distributed to more than 300 contacts from more than twenty countries globally.

Value Statement/Synopsis: WOGS newsletters provide both timely information and a repository of information that can be accessed as needed for training, education, and research needs.

Introductory HACCP Training

Project Leader: Dianna Bourassa

Institutional Lead: 1862 Extension – AU

Project Objectives: Review the philosophy and principles of the Hazard Analysis and Critical Control Point System and discuss the implementation of HACCP in poultry or meat plants.

Background/Situation/Issue: Poultry and meat processors are required by the U.S. Department of Agriculture to have certified training in HACCP systems in order to operate an inspected poultry or meat processing facility.

Outputs: The first Introductory HACCP Training course was completed and provided certification by the International HACCP Alliance to all participants.

Value Statement/Synopsis: The Introductory HACCP Training course allows poultry and meat processors to develop new HACCP programs and to review and assess current practices. This training also allows companies to fulfill USDA regulatory requirements for HACCP training.

Small Flocks

Project Leader: Brigid McCrea

Institutional Lead: 1862 Extension – AU

Co-Leaders/Collaborators: Dianna Bourassa and Wilmer Pacheco

Project Objectives: To educate small flock owners about raising chickens and other poultry. The focus this year is on good management and biosecurity as well as grading and sizing eggs. Additionally, a 1-day conference was coordinated and held (Cooptastic).

Background/Situation/Issue: Backyard chicken keeping is the nation’s fourth largest poultry industry, with approximately 212.5 million layers and 16.9 million owners nationally (pre-COVID). This underserved audience is desperate to learn more about how to raise their flocks, and they often turn to unreliable sources of information to receive instruction. Correspondingly, there are some diseases that easily cross the species barrier from chickens to wild birds and vice versa, and occasionally cause humans to become sick. These diseases not only put backyard flocks at risk but humans and commercial poultry flocks as well.

Social Media Channels: A total of 159 Facebook posts were made between January and June of 2023.

Outputs: The small flock poultry program held several in-person workshops throughout the state as invited and organized by county Extension coordinators. On the topic Getting Started with Chickens, a total of eleven meetings were held, reaching a total of 132 people. On the topic All About Eggs, a total of four meetings were held, reaching a total of twenty people. An ANFR publication was developed on parasitic red mites: “Poultry Red Mites: Identification, Prevention, and Treatment.” Two eTV ads were run: (1) Cooptastic and (2) footbaths for small flocks. Four articles in Chicken Whisperer magazine reached over 200,000 readers: (1) “Egging as an Art,” spring 2023; (2) “The Cost of Raising Chickens,” spring 2023; (3) “The Stealthy Chicken Red Mite,” spring 2023; and (4) “Cleaning Eggs with Sound,” fall 2023. Lastly, Cooptastic was a 1-day conference for backyard chicken owners held on March 4, 2023; seventy-three evaluation forms were received.

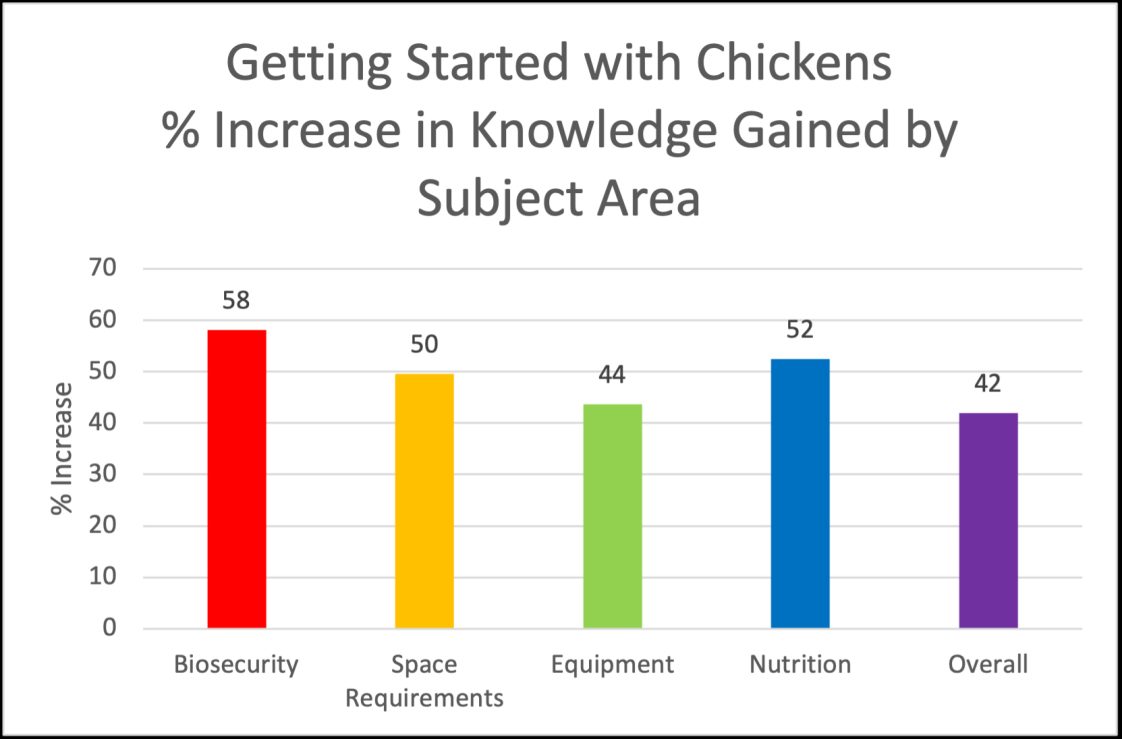

Evaluation Techniques: Paper surveys were used. For small flock owners (or future owners) who attended the eleven Getting Started with Chickens presentations, there was a consistent increase in knowledge (58 percent in biosecurity; 50 percent in space requirements; 44 percent in equipment; 52 percent in nutrition; and an overall 42 percent in poultry knowledge).

Evaluation Techniques: Paper surveys were used. For small flock owners (or future owners) who attended the eleven Getting Started with Chickens presentations, there was a consistent increase in knowledge (58 percent in biosecurity; 50 percent in space requirements; 44 percent in equipment; 52 percent in nutrition; and an overall 42 percent in poultry knowledge).

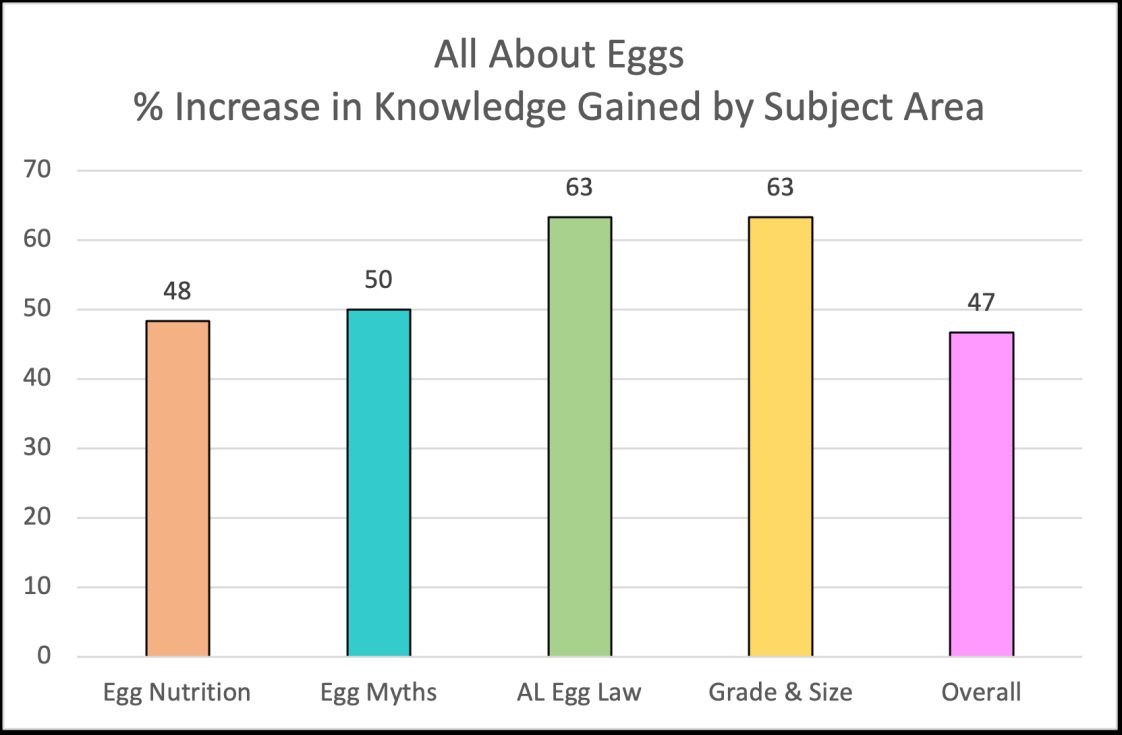

There was also a consistent increase in knowledge among participants that attended the four All About Eggs presentations. There was a 48 percent increase in knowledge of egg nutrition and 50 percent increase in knowledge about egg myths. Knowledge about the Alabama Egg Law and how to grade and size eggs both increased by 63 percent. Participants indicated an overall increase in egg knowledge of 47 percent. A total of 162 eggs were tested as part of the free egg testing. These eggs came from seven different flocks.

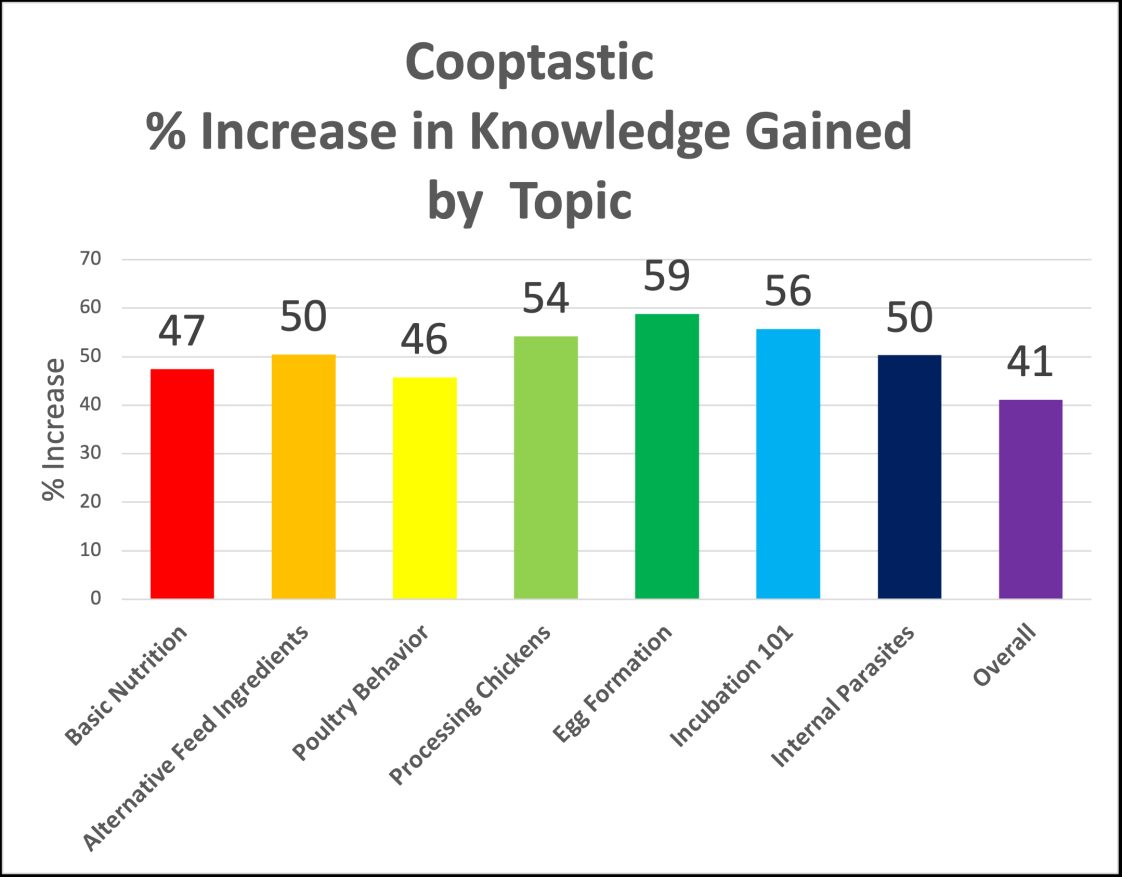

Cooptastic was held on March 4, 2023, at the Alabama 4-H Center, and seventy-three evaluations were received. There was a consistent increase in knowledge among attendees at this conference: 47 percent in basic nutrition, 50 percent in alternative feed ingredients, 46 percent in poultry behavior, 54 percent in processing chickens, 59 percent in egg formation, 56 percent in incubation, 50 percent in internal parasites, and 41 percent in overall chicken knowledge.

Revenue Generation: $650.25 in-kind donation from Stromberg’s; $1,600 from Cooptastic registrations.

Revenue Generation: $650.25 in-kind donation from Stromberg’s; $1,600 from Cooptastic registrations.

Testimonials: Attendees from the Getting Started with Chickens presentation said the following:

- “I will seek out science-based information.”

- “Clean! Cleaning is the best way to maintain a healthy flock.”

- “Chickens are hard work. They need 14 hours of light to lay eggs.”

- “Chickens are a lot of work. A commitment. We need to prepare everything before getting chickens.”

- “I’ll remember the importance of keeping wild birds and chickens separate and also keeping things clean or separate.”

- “Chickens are a lot, and now I am reconsidering the decision.”

Attendees from Cooptastic said the following:

Attendees from Cooptastic said the following:

- “Poultry behavior was excellent! I really enjoyed the info, and it was new to me.”

- “The opportunity to listen to each person and hear their teachings and opinions. I have learned a lot.”

- “All the info was great; really liked the breakdown that was done; everything delivered at level to understand.”

- “I will look at what I am feeding my chickens at all stages to make sure they are getting what they need. Cut back on treats.”

- “Basic principles on maintaining a healthy flock.”

- “Washing eggs and refrigerating more quickly.”

Alabama Cooperative Extension System Poultry Team

New March 2024, Poultry Team Outcomes & Impact Report 2023, ANR-3063

Past Reports

The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) is an equal opportunity educator, employer, and provider. If you need a reasonable accommodation or language access services, contact Dianna Bourassa at dvb0006@aces.edu.