Farming

Maintaining minimum ventilation and proper moisture control are essential for poultry house operation in cold weather. Learn tips for preparing houses for efficient and effective cold weather management.

Block the Correct Vents

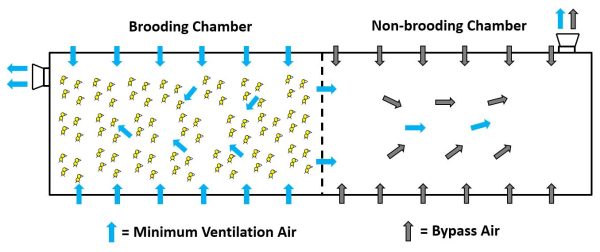

One of the most common minimum ventilation mistakes made by producers during brooding is not blocking vents. The perimeter air inlets (vents or baffles) on the non-brooding end (off end or grow-out end) should be blocked off during brooding to ensure that minimum ventilation air enters the barn in the brooding chamber first and targets the ceiling peak.

Air that enters and exits the non-brooding area of the house does not count toward minimum ventilation. Only air that enters the bird area counts. Thus, air allowed to enter and exit the non-brooding ends and bypass the brooding chamber should be deducted from minimum ventilation calculations. Using all the perimeter inlets in the barn during minimum ventilation without compensating for this air bypass could be a mistake.

Figure 1 is an example where 50 percent of the ventilation air is bypassing the brooding chamber. Notice that one fan is ventilating the brooding chamber and the other is ventilating the non-brooding chamber. If the producer is counting both fans toward minimum ventilation, the air exchange in the brooding chamber will not be enough, and the results will likely be undesirable. To compensate for the off-chamber bypass ventilation, minimum ventilation run time of 60 seconds ON (240 seconds OFF) would need to be increased to 120 seconds ON (180 seconds OFF). This would be a good starting point.

Figure 1. Example of a common minimum ventilation setup where moisture can be difficult to get under control.

In this case, improving brood chamber air exchange is a matter of either adding the additional time or closing the non-brooding area vents. It is acceptable to open some vents in the back of the house, but keep in mind that air does not count toward minimum ventilation. We are looking for a vent opening of about 1 1⁄2 to 2 inches. For some houses, this cannot be achieved without blocking selected vents to get the proper opening.

Proper inlet door opening is very important for bird comfort, moisture removal, and uniform floor temperatures. This opening must be routinely checked and adjusted when necessary for optimum minimum ventilation performance.

Following are tips on vent management and moisture control:

- Check for missing vent door insulation. All perimeter vents must be fully insulated so that they tightly close when not in use. Any missing insulation will likely be the source of a cold-air leak that throws air directly to the floor. This air works against litter drying (incomplete pass), drafts chicks in the vicinity, causes uneven floor temperatures, and causes excessive heater run time. If the insulation cannot be repaired, it is time to replace the door.

- The insulation in figure 2 has been damaged by rodents. The door opens and shuts but does not seal when closed and is leaking on three sides. It is overdue for repair or replacement. This often is found on inlets located closest to the feed cross-fill entrance to the house, where rodents have direct access to the house wall and attic space.

- The vent in figure 3 is another major source of air leakage. The leakage is made worse by the insulation that is settling out of the door and getting wedged between the door and frame. The metal door appears to be in good shape, so the recommendation is to replace the insulation on this door.

- Figure 2: This inlet door is a considerable source of air leakage when shut.

- Figure 3: The insulation in this inlet door is almost totally disintegrated by darkling beetles.

- Figure 4: This photo of a blocked vent was taken from inside the house looking through the sidewall vent.

- Monitor vents in front of temperature sensors. You do not want cold outside air landing directly on sensors. Air inlets that are directly adjacent to temperature sensors must be shut off to keep this from happening. Leaving these vents open can cause unnecessary temperature fluctuations, excessive heater run times, and bird movement away from this zone. If you notice a zone that is running significantly more than others, monitor heater zone run times during brooding. This can sometimes help you spot a potential problem. It is common for the front and back brooding chamber zones to operate more than the middle zones due to heat being lost through the brood curtain or end wall.

- Clean dirty exterior bird wire. Vent screens can become partially or almost entirely blocked off by dust, feathers, and dander. This is especially true for vents that are located adjacent to sidewall exhaust fans or across from tunnel fans of adjacent houses. Keep all perimeter inlet bird wire clean to ensure that all vents used are capable of unrestricted inlet airflow.

- Figure 4 shows bird wire that is almost 70 percent blocked by dust and feathers. It was next to a sidewall exhaust fan. This vent wire is way overdue for a good cleaning.

- Repair or replace damaged doors. Every inlet door in use should open evenly and by the same amount during each minimum ventilation cycle. Repair or replace any bent, rusted, or damaged doors prior to cold weather operation. Any damage that keeps the door from shutting or opening (whether partially or completely) may result in cold air landing on the birds, drinkers, and litter, causing more harm than good.

- Inspect cables and sprockets. Vent cables can stretch over time and create uneven door openings and leave vent doors at the ends partially open when they should be sealed shut. Take time to adjust vent door connections to make sure all doors open by the same amount. Leaving doors open unevenly will cause excessive heater run times in those locations. Sprockets must be greased and pulleys inspected for signs of wear and possible failure.

- Look for vents without latches. Simple, inexpensive vent door latches can be purchased from your local dealer or online retailer. They also can be handmade, provided the finished product is fully functional. Many poultry houses are not designed to operate without closing a select number of vents during cold weather brooding. If you struggle with moisture control during cold weather, this could be part of the reason.

Maintain Minimum Ventilation Fans

Minimum ventilation fans are the most important fans on the farm. Tackle needed maintenance right away.

Minimum ventilation fans in a broiler house cycle every 5 minutes (300 seconds). Every hour these fans start and stop 12 times. Every day these fans start and stop 288 times. During cold weather, when the house stays in minimum ventilation for the full brooding cycle (about 10 days), these fans cycle 2,880 times. If we conservatively estimate that these fans were used for seven flocks and only used during brooding, then the cycle is 20,160 times in a single year! This is just for the time they run during minimum ventilation. These fans require more routine inspection and maintenance. Focus here can make you, and neglect can break you.

In addition to their high workload, these same fans operate under high static pressure of 0.10 to 0.16 inches of water column every time they run. These fans often are wet with condensation and covered with dust and dander. Dirty interior fan shutters cause these fans to work even harder during operation.

For example, suppose that the current fans used for minimum ventilation are operating at 60 percent of the original designed capacity. The only way to get adequate moisture removal is to add an additional 40 percent to the current minimum ventilation time to make up for the inferior capacity. This additional 40 percent run time will have to be maintained throughout the flock if the fans are not properly tuned up.

Now is the time to conduct a complete tune-up on all fans used for minimum ventilation. This means a complete and thorough inspection of each minimum ventilation fan for any problems that would hinder (or potentially hinder) performance and air exchange.

Following are tips on vent management:

- Perform shutter and light trap maintenance. Shutters must be cleaned after every flock. Any damaged shutter blades, rail guides, butterfly springs, or blades stuck in the open position must be repaired or replaced. Sometimes shutters need a good cleaning during a flock as well. All pullet house minimum ventilation fans must have light traps removed, inspected, and thoroughly cleaned after every flock.

- Figure 5 shows a pullet house where the light traps, shutters, and fans likely had never been cleaned. There was about 1⁄4 inch of dust on shutters, about 2 1⁄2 to 3 inches of dust settled in the bottom of the light traps and framing, about 1 to 1 1⁄2 inches of dust in the fan housing, and totally dust-covered light traps.

- Check belts. All minimum ventilation fan belts should be new or like new. Compare used belts to new ones or measure them to determine if they are adequate. Don’t assume they are good—verify. If you can hear the fan squeal on the motor pulley, fix the fan.

- Test tensioners. All fan tensioners must be lubricated, exercised, and tested for worn or dry bearings. If the bearing is frozen and the belt is cutting into the pulley, replace it with a new one. Most tensioners freeze up in the relaxed position, so make sure the tensioner is placing some stretch force on the belt.

- The fan in figure 6 was still in operation, and the belt was cutting into the plastic pulley when the tensioner pulley failed. The squealing noise due to the friction between the belt and plastic pulley could be heard from outside the house.

- Maintain bearings. All bearings must be greased or replaced. Don’t leave a dry bearing on a fan. Get it fixed.

- Figure 5a. These photos were taken of a pullet house that was only 5 years old.

- Figure 5b. These photos were taken of a pullet house that was only 5 years old.

- Figure 6. The bearing inside this tensioner pulley failed, and the pulley no longer turned.

Conclusion

It is general practice to maintain house relative humidity between 50 and 70 percent during cold weather. Check humidity first thing in the morning for best results, and make adjustments. Blocking the correct vents forces air to target the ceiling peak (or as close as possible) so that the incoming air can acclimate, mix, and provide fresh air to the house and birds. This is how moisture is removed from the house. You want this to happen as evenly down the house as possible. Some variations to this are acceptable, and this will take some experimenting and adjusting to make it work properly for each house and farm.

You need every possible cubic foot per minute (CFM) of each fan used for minimum ventilation to work at maximum capacity in every cycle. Anything less than 100 percent is a loss in adequate air exchange and static pressure ability. Any inadequacy in fan performance will have to be made up with additional run time. Don’t forget the importance of house tightness and the use of stirring fans during cold weather.

For more information, contact Jess Campbell, jesscamp@aces.edu, (334) 332-6830.

Jess Campbell, Extension Assistant Professor, Jeremiah Davis, Associate Professor and Director, John Linhoss, Kelly Griggs, Cody Smith, Carson Edge, and Martha Rueda, all with National Poultry Technology Center

Jess Campbell, Extension Assistant Professor, Jeremiah Davis, Associate Professor and Director, John Linhoss, Kelly Griggs, Cody Smith, Carson Edge, and Martha Rueda, all with National Poultry Technology Center

New January 2022, Cold Weather Ventilation & Moisture Control of Poultry Houses, ANR-2849