Farming

Electrical disconnects, generators, transfer switches, and electrical panels must be in top working order before the 2022 hot weather begins.

Spring is the time to ensure that your electrical system is properly tuned up. Why in the spring? Labor and supply chain shortages have touched everyone. Motors, large fuses, electronic control parts, boxes, and other electrical parts can be hard to source. This means planning is required. Order in the spring so you will have time to get the parts you need before summer. Remember to think about safety first and de-energize before working with any electrical system. Alabama Extension recommends that you use a trained professional for work on major equipment.

Main Farm Disconnect Tips

Inspect It

1. Spare breakers and fuses must be on hand in the generator shed (or equivalent) in case one is damaged or blown. Some of these items may be in short supply.

2. A trained or licensed electrician should inspect the internal components of the disconnect to make sure that there are no signs of wear or damage that may cause a failure.

3. All main supply wire connections should be verified for tightness.

4. These units are often installed outside so they must be checked to make sure that no water is entering the box from the weather head. Main disconnects have been seen with water standing inside the bottom of the box.

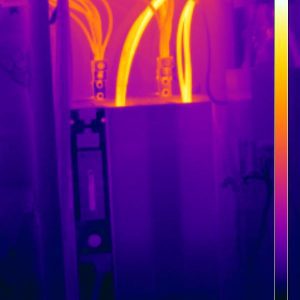

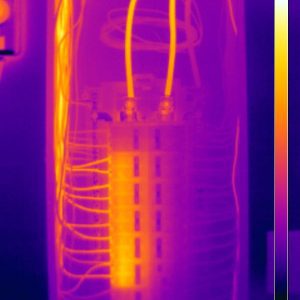

Figure 1 is a thermal image of a main disconnect under full load in hot weather. These fuses are hot and warrant a closer inspection to determine if the disconnect is overloaded. Taking thermal images of electrical equipment under full load can be very informative and a useful tool for spotting potential failures before they happen. Figure 2, believe it or not, is also a disconnect.

- Figure 1. Potentially overloaded disconnect

- Figure 2. Neglected disconnect

Generator Tips

Professionally Service It

5. The next time you are out of birds, conduct a generator backup test and run the system under load for several hours to make sure that it will get the job done.

6. Batteries should be inspected, load tested, and terminals cleaned every year at a minimum. A good battery is extremely important. The generator must be test cycled under load weekly.

7. Oil, fuel, and air filters should be changed yearly regardless of condition. Keep spare fuel filters on hand as recommended by your generator service professional.

8. Avoid dirty radiators. A clogged radiator will not allow the cooling necessary to keep your unit running under load. This inspection only requires a flashlight and 5 minutes of your time. Hint: inspect the fan side of the radiator to spot a problem.

9. Fuel age, condition, and tank fill are extremely important. Spring is the time to take a hard look at the fuel in your system. Is it fresh, do you have enough, and do you have any backup fuel?Ask your generator service person about using fuel additives to maintain fuel conditions and prevent problems associated with fuel storage.

Figures 3 and 4 are both generator batteries. Figure 3 shows a battery that has clean connections, a date (almost 5 years since installation and past due for replacement), and has obviously had the water levels in the battery inspected. The battery in figure 4 has no clear signs of servicing.

- Figure 3. Serviced battery

- Figure 4. Neglected battery

Transfer Switch Tips

Exercise It

10. Exercise each transfer switch under load the next time you are out of birds to make sure it works. Practice makes perfect so make sure that you and anyone who might need to transfer emergency power on the farm knows how to do this safely. Label all switches and electrical boxes to help with this process.

11. All wire connections including grounds need to be checked by a trained or licensed electrician. Safety first. Inspect, repair, or replace items as needed for proper operation.

12. The electronic and internal components on these units might be hard to source, so don’t wait to repair them if you know you might have an issue.

13. All unused holes in the exterior enclosure (box) must be covered with metal to keep insects, pests, birds, and snakes out of the transfer switch. Animal remains, nests, and trash are found left inside of them too often.

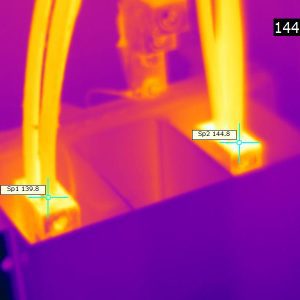

Figures 5 and 6 are two pictures of the same transfer switch under full load. The connections shown in figure 6 are acceptable temperatures but still require closer inspection to make sure that the uneven temperatures are due to electrical loading on the wires and not a weakening connection on the right connection.

- Figure 5. Transfer switch under load

- Figure 6. Thermal image of wire connections in transfer switch

Main Panel Tips

Clean It

14. Every farm should have at least one spare main breaker in stock in case one fails with birds present. This is extremely important to have on hand.

15. All main wire connections should be inspected for tightness and visual signs of damage.

16. At least one spare breaker of each size and type (single or double pole) should be on hand for quick replacement in case of a failure.

17. All unused holes must be covered with a metal blank, and every panel should be cleaned out or vacuumed to keep things in order.

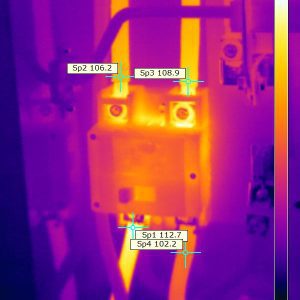

Figure 7 shows a main panel with five fans operating through the breakers on the left side. Figure 8 is a thermal image of a disconnect breaker supplying a house under load. Notice the bottom left connection (112.7 degrees F) is visually much warmer than the others. This should be inspected closer to see if the connection needs to be tightened.

- Figure 7. Thermal image of main panel in use

- Figure 8. Thermal image of disconnect breaker in use

Alarm System Tips

Test It

18. Don’t take a chance on a weak battery keeping you from getting an alarm. Install a new one.

19. Test sirens and power failure system calls to make sure they are operating properly.

The Bottom Line

Catastrophic losses during hot weather are devastating to everyone involved, and in some cases, could have been prevented. Remember these critical electrical tips and take preventative maintenance action. A few hundred dollars spent on electrical inspections, repairs, and spare parts could save thousands in emergency repairs, or worse, a partial or total flock loss. If you don’t already have a good relationship with an electrician and generator service professional, now is a great time to build one. Be proactive.

Please visit the National Poultry Technology Center (NPTC) website at poultryhouse.com, download the Poultry Toolkit smartphone app, or contact Jess Campbell at (334) 332-6830 or jesscamp@aces.edu for more information.

Jesse Campbell, Assistant Extension Professor; Jeremiah Davis, Associate Professor, Director NPTC; John Linhoss, Kelly Griggs, and Cody Smith all with the NPTC at Auburn University

Jesse Campbell, Assistant Extension Professor; Jeremiah Davis, Associate Professor, Director NPTC; John Linhoss, Kelly Griggs, and Cody Smith all with the NPTC at Auburn University

New March 2022, 19 Spring Tune-Up Tips for Poultry Farm Generators & Electrical Systems, ANR-2878