Crop Production

Alabama Extension’s research-based integrated pest management (IPM) field crop trials and programs help producers across the state make decisions to improve and protect crops. This includes information on the selection, rates, application, and safe and proper use of pesticides.

Extension funding for most of the 2020 field trials was provided by the Alabama Cotton Commission. This funding also supports field visits, scout and REA trainings, moth trapping, resistance monitoring, and testing of various insect control technologies and thresholds. In-season pest updates from in-season monitoring and up-to-date insect pest outbreaks are distributed via Twitter, the Alabama Crops Report Newsletter and the Alabama Cotton Shorts Newsletters. Data from these experiments are used to validate or modify thresholds and recommendations in Alabama Extension’s “Cotton Insect, Disease, Nematode, and Weed IPM Recommendations Guide” (IPM-0415). Following are selected cotton IPM projects across the state.

Pheromone Moth Trapping

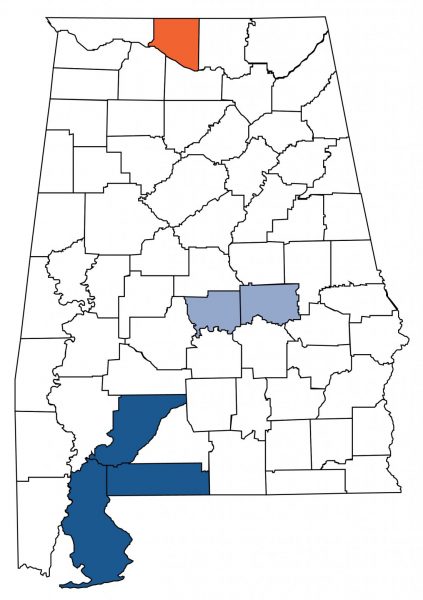

Figure 1. Locations of pheromone traps in 2020

Although few escaped bollworms from 2-gene Bt cottons have been experienced since 2017, resistance has been established across Alabama to the Cry1 and Cry2 Bt toxins (Bollgard 2, Widestrike, TwinLink). No cases of bollworm resistance are currently known to Vip3A (Bollgard 3, Widestrike 3, TwinLink Plus) in Alabama. In the mid-south and parts of the southeast, some 2-gene cotton fields require foliar insecticides to avoid economic losses from bollworms. The use of area-wide pheromone traps can provide historical references for when to expect peak flights of bollworms and provide information for in-season flights as well. Knowing when the peak flight occurs helps scouts and agrifield representatives know when to focus efforts on looking for bollworm eggs and escaped larvae. Pheromone trapping was also done for soybean looper, a pest of non-Bt cotton, soybeans, and peanuts.

In 2020, pheromone traps were placed on research stations and grower fields in Madison, Autauga, Elmore, Monroe, Escambia, and Baldwin Counties (figure 1). Hartstack traps were baited with pheromone from Great Lakes IPM (Vestaburg, Michigan) and changed every two weeks. Traps were monitored on seven-day intervals from mid-June through the end of August or mid-September by the Extension cotton entomology team and on-station personnel across the state.

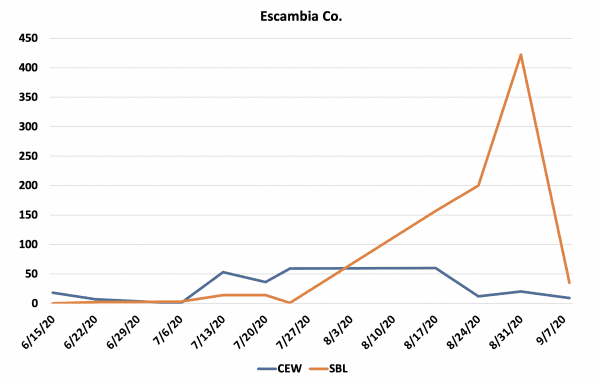

Overall, the peak bollworm flight in 2020 did not match the historical flight dates (South Alabama ≈ July 10; Central Alabama ≈ July 20; North Alabama ≈ August 1). The bollworm flight highly depends on the corn planting window. If corn attractive to moths (silking and blister stages) is present, bollworms will preferentially go there before moving to cotton, peanuts, or soybean. Thus, corn planted in a short window yields a rather distinct peak flight (figure 2), while corn planted over a long period leads to a “trickle effect” of moths leaving corn.

Table 1. Total Numbers of Bollworm and Soybean Looper Moths Collected in Hartstack Traps across Alabama

*Total bollworm counts include Old World Bollworm (H. armigera).

| Trap Location | Total Bollworms* | Total Soybean Loopers |

|---|---|---|

| Madison County | 933 | 1,212 |

| Autauga County | 227 | 1,359 |

| Elmore County | 1,803 | 2,050 |

| Monroe County | 375 | 1,755 |

| Escambia County | 274 | 848 |

| Baldwin County | 4,347 | 2,063 |

| Total Collected | 7,959 | 9,287 |

The soybean looper (SBL) flight appeared to be closer to the historical expectation. Because SBL do not overwinter in Alabama, they must migrate up from southern latitudes. SBL populations are typically expected to build from August through September. In 2020, much of the sustained SBL flight began in mid-August.

In the Tennessee Valley (Madison County), the highest number of bollworms caught (=758) was earlier than expected (June 16–29) while the peak number of SBL caught (=822) was closer to when expected (August. 17–31). In central Alabama (Elmore Count.), the peak bollworm flight (=1,227) was later than expected (=July 31–Aug. 14). The highest number of SBL moths caught in Elmore County (=512) was early (July 17); however, the peak sustained flight (=896) was in August (Aug. 14– 27). In south Alabama, Baldwin County had the highest pressure of both species. High numbers of bollworm and SBL were first collected on July 10 and were sustained until traps were taken down on September 10.

Figure 2. Example of the “trickle effect” of bollworm moths beginning around the expected historical flight date (July 10) and the 2020 soybean looper flight in Escambia County.

Insecticide and Bt Cotton Efficacy Bt Resistance Monitoring

Multiple replicated, small-plot trials are conducted annually on research stations across Alabama to evaluate current and future insect control strategies. This research helps to refine insecticide recommendations provided in Alabama Extension’s “Cotton Insect, Disease, Nematode, and Weed IPM Recommendations Guide” (IPM-0415). Plot sizes may be 4 to 8 rows wide and 25 to 30 feet long. Trials are initiated when the target pest population reaches threshold and are evaluated at intervals ranging from 3 to 14 days after application (DAA).

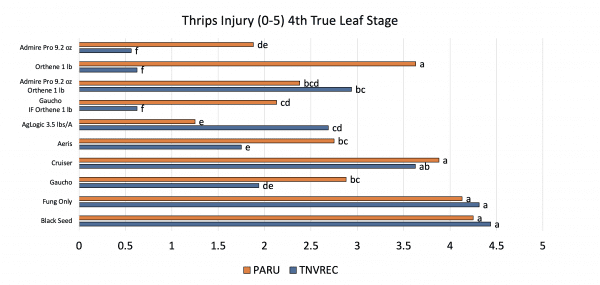

Efficacy of Thrips Management Options for Reducing Damage and Preserving Cotton Yields. Studies were conducted at the Prattville Agricultural Research Unit (PARU) in Prattville, Alabama and at the Tennessee Valley Research and Extension Center (TNVREC) in Belle Mina, Alabama, to evaluate selected seed and in-furrow treatments against thrips infesting seedling cotton. To evaluate treatments, whole plot thrips injury ratings were made on a 0 to 5 scale. On this scale, “0” means no injury is observed, “3” is considered the threshold when delays in maturity are likely and yield loss is possible, and “5” means thrips have killed all the plants in the plot. Although initial thrips injury ratings were higher at PARU, both locations had significant pressure at the final rating. Except for Cruiser and Orthene 97S at PARU, all treatments significantly reduced thrips injury ratings compared to the untreated controls (black seed, fungicide only) (table 2). As has been consistently reported across the mid-south and southeast, Cruiser performed poorly at both locations, while Orthene performance was different at each location (figure 3). Although no significant differences in yield were observed among treatments, using a recommended at-plant insecticide yielded an average of ≈117 pounds of lint per acre compared to the untreated control (table 3). These data show a consistent return on investment when using an at-plant insecticide to manage thrips in seedling cotton. Results from this study have also led to the removal of Cruiser for thrips management from Alabama Extension’s “Cotton Insect, Disease, Nematode, and Weed IPM Recommendations Guide” (IPM-0415).

Table 2. Impact of At-Planting Treatment on Thrips Injury for Cotton Planted at Prattville and Belle Mina (2020)

| Treatment | Application | Rate | Injury Rating – PARU 1.5-leaf | Injury Rating – PARU 4-leaf | Injury Rating – TNVREC 1.5-leaf | Injury Rating – TNVREC 4-leaf |

|---|---|---|---|---|---|---|

| Black Seed | None | 3.50 a | 4.25 a | 2.19 ab | 4.44 a | |

| Fungicide Only | Seed | 3.38 a | 4.13 a | 2.44 a | 4.31 ab | |

| Cruiser | Seed | 0.341 | 3.00 a | 3.88 a | 1.88 ab | 3.63 bc |

| Gaucho | Seed | 0.3751 | 2.00 b | 2.88 b | 1.00 d | 1.94 ef |

| Aeris | Seed | 0.752 | 2.13 b | 2.75 bc | 0.88 d | 1.75 f |

| AgLogic 15GG | In-Furrow | 3.53 | 1.25 c | 1.25 e | 1.81 bc | 2.69 de |

| Gaucho + Acephate 97S | In-Furrow | 0.3751+1.03 | 2.13 b | 2.13 cd | 0.69 d | 0.63 g |

| Admire Pro 4.6SC + Orthene 97S | In-Furrow | 9.24+1.03 | 2.00 b | 2.38 bcd | 1.25 cd | 2.94 cd |

| Orthene 97S | In-Furrow | 1.03 | 3.38 a | 3.36 a | 0.81 d | 0.63 g |

| Admire Pro 4.6SC | In-Furrow | 9.24 | 1.5 bc | 1.88 de | 0.75 d | 0.56 g |

| P>F | P<0.001 |

Figure 3. Final thrips injury ratings (0 to 5 scale, 4th leaf) in at-plant seed and in-furrow insecticide trials in Prattville and Belle Mina, Alabama (2020). Letters indicate significant differences (P<0.05).

Table 3. Impact of At-Planting Treatment for Thrips on Cotton Yields at Prattville and Belle Mina (2020)

| Treatment | Application | Rate | PARU – Lint/Acre | PARU – Lint/A vs Black Seed | TNVREC – Lint/Acre | TNVREC – Lint/A vs Black Seed |

|---|---|---|---|---|---|---|

| Black Seed | None | 891.8 a | 986.2 a | |||

| Fungicide Only | Seed | 876.9 a | -14.8 a | 1,015.2 a | 29.0 a | |

| Cruiser | Seed | 0.341 | 876.9 a | -14.8 a | 1,024.2 a | 37.9 a |

| Gaucho | Seed | 0.3751 | 980.4 a | 88.7 a | 947.8 a | -38.5 a |

| Aeris | Seed | 0.752 | 928.7 a | 36.9 a | 1,053.2 a | 67.0 a |

| AgLogic 15GG | In-Furrow | 3.53 | 1,032.2 a | 140.4 a | 1,103.1 a | 116.9 a |

| Gaucho + Acephate 97S | In-Furrow | 0.3751+1.03 | 970.6 a | 78.8 a | 1,273.1 a | 286.9 a |

| Admire Pro 4.6SC + Orthene 97S | In-Furrow | 9.24+1.03 | 992.7 a | 100.9 a | 1,166.4 a | 180.2 a |

| Orthene 97S | In-Furrow | 1.03 | 995.2 a | 103.4 a | 1,314.3 a | 328.1 a |

| Admire Pro 4.6SC | In-Furrow | 9.24 | 918.8 a | 27.1 a | 1,108.6 a | 122.4 a |

| P>F | P>0.05 |

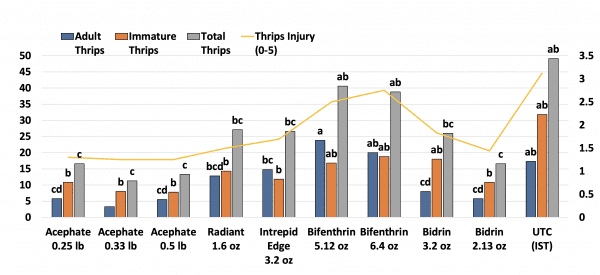

Efficacy of Foliar Insecticides for Supplemental Thrips Management. A trial was conducted on a grower field in Madison County, Alabama, to determine the efficacy of several foliar insecticides to supplement insecticide seed treatment control of thrips in cotton. Plots were four rows by 100 feet long and replicated four times. Foliar treatments were applied when cotton was at the first true leaf stage on June 11, 2020. Evaluations were made at 7 DAA and included thrips injury ratings (0 to 5 scale, 0= no injury; 3= threshold; 5= plant death) and estimations of thrips populations by collecting 10 plants from each plot and counting thrips under a microscope in the lab. Results from this trial support current recommendations of 0.25-0.3 lbs/A of acephate for the supplemental control of seedling thrips. This study also demonstrates that alternative products, such as Radiant or Intrepid Edge, can provide the necessary reduction of thrips pressure with less likelihood of flaring secondary pests, such as spider mites. Last, this trial provides data showing that pyrethroids no longer provide control of thrips (table 4, figure 4). As resistance to seed treatments continues to develop, the efficacy of foliar thrips sprays will become more important. Proper selection of chemistries in high pressure situations will be key.

Table 4. Efficacy of Foliar Insecticides to Supplement Insecticide Seed Treatment (IST) Control of Thrips in Madison County (2020)

Means within a column followed by a common letter are not significantly different (FPLSD P=0.05).

| Treatment | Application | Rate/Acre (oz) | Injury Rating | Thrips per 10 Plants |

|---|---|---|---|---|

| IST | None | 3.12 a | 49.1 ab | |

| Orthene 97S | Foliar | 4 | 1.3 c | 16.6 c |

| Orthene 97S | Foliar | 5.3 | 1.25 c | 11.3 c |

| Orthene 97S | Foliar | 8 | 1.25 c | 13.3 c |

| Radiant | Foliar | 1.6 | 1.5 bc | 27.1 bc |

| Intrepid Edge | Foliar | 3.2 | 1.5 bc | 26.6 bc |

| Bifenthrin | Foliar | 5.12 | 2.5 ab | 40.6 ab |

| Bifenthrin | Foliar | 6.4 | 2.75 ab | 38.8 ab |

| Bidrin | Foliar | 2.13 | 1.44 c | 16.6 c |

| Bidrin | Foliar | 3.2 | 1.83 cd | 26.0 bc |

| P>F | P<0.001 |

Figure 4. Evaluation foliar insecticides to provide supplemental control of thrips in seedling cotton in Madison County, AL (2020).

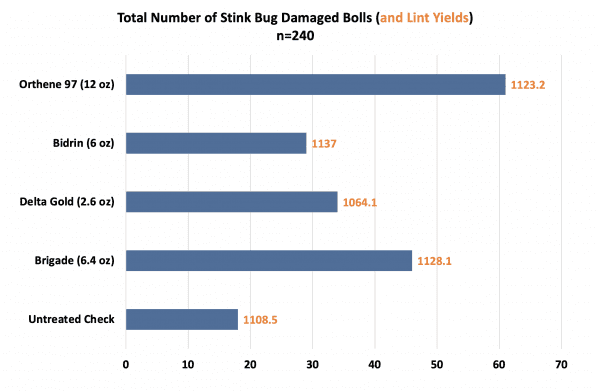

Management Strategies and Efficacy of Insecticides for Stink Bugs in Cotton. A trial was conducted at the Prattville Agricultural Research Unit (PARU) in Prattville, Alabama, to evaluate selected insecticides to manage stink bugs in cotton. When plots reached at least threshold (=10% injury), the trial was initiated. Application A was made during the fourth week of bloom on July 20,2020, and application B was made during the sixth week of bloom on August 3, 2020. Ratings were made at 7 and 14 days after application A (DAA) and at 7 and 14 days after application B (DAB). To sample, 15 bolls were collected from each plot at each evaluation (n= total 240 bolls per treatment) and sampled for internal signs of stink bug injury (puncture wounds, warts, stained lint).

All treatments reduced stink bug injury compared to the untreated check at 7 DDA, while Bifenthrin, Delta Gold, and Orthene kept injury below threshold (=10%). By 14 DAA, only Orthene provided control significantly better than the untreated check and below threshold (=10%). No treatment separated from the untreated check at 7 DAB; however, all were below threshold (=30%). At 14 DAB, all treatments were below the injury threshold (=50%) and significantly lower than the untreated check (table 5). There were no effects of treatment on yields; however, this study shows that acephate can be used as an effective chemistry to control stink bug injury (figure 4).

Table 5. Impact of Selected Insecticides on Stink Bug Injured Bolls in Prattville (2020)

Means within a column followed by a common letter are not significantly different (FPLSD P=0.05).

| Treatment | Active Ingredient | Rate/Acre (oz) | 7 DAA TH = 10% % Dam. Bolls | 14 DAA TH = 10% % Dam. Bolls | 7 DAB TH = 30% % Dam. Bolls | 14 DAB TH = 50% % Dam. Bolls |

|---|---|---|---|---|---|---|

| Untreated | None | 20.0% a | 25.3% ab | 18.7% a | 18.7% a | |

| Brigade | Bifenthrin | 6.4 | 5.3% b | 29.0% ab | 6.7% a | 6.7% b |

| Delta Gold | Deltamethrin | 2.6 | 5.3% b | 13.3% bc | 25.3% a | 25.3% b |

| Bidrin | Dicrotophos | 6 | 12.0% b | 32.0% a | 18.7% a | 18.7% b |

| Orthene | Acephate | 12 | 3.3% b | 6.7% c | 15.3% a | 15.3% b |

| P>F | P<0.001 |

Efficacy of Selected Insecticides to Manage Tarnished Plant Bugs in Blooming Cotton. Trials were conducted at the Tennessee Valley Research and Extension Center (TNVREC) in Belle Mina, Alabama, to evaluate insecticides against tarnished plant bug (TPB) in cotton. Trials were initiated when TPB populations at least reach threshold (=3/5 rft) during peak bloom (August 8).

Trial One. Tarnished plant bug counts were done on 7 and 14 DAA by taking two black drop-cloth samples (=10 rft) in the center two rows of each plot. Although no significant differences were observed between treatments, Transform, Bidrin, and Bidrin + Diamond appeared to provide better control than other treatments and the untreated check (table 8). No significant differences were observed for yield; however, several treatments, such as Transform, Bidrin, and Bidrin + Diamond, provided substantial yield protection over the untreated check (table 6). These data support the decline in efficacy of pyrethroids for TPB management in north Alabama. The limited yield return from neonicotinoids suggests that these products should not be used to manage immature plant bugs; however, they are still effective against adult populations prior to bloom. Although Bidrin and Transform both provided good control, it is possible that Bidrin provided higher yield protection over Transform due to the added stink bug control.

Table 6. Impact of Selected Insecticides to Manage Tarnished Plant Bugs in Belle Mina (2020)

Means within a column followed by a common letter are not significantly different (FPLSD P=0.05).

| Treatment | Class of Chemistry | Rate/Acre (oz) | 7 DAA TH = 6 TPB/10 rft | 14 DAA TH = 6 TPB/10 rft | Yield Lint/A | Lint/A vs UTC |

|---|---|---|---|---|---|---|

| Untreated | none | 6.0 a | 7.0 a | 1,592.7 a | ||

| Centric | neonicotinoid | 2 | 3.8 a | 6.3 a | 1,610.8 a | 18.4 |

| Admire Pro | neonicotinoid | 1.7 | 8.0 a | 4.5 a | 1,594.4 a | 2.7 |

| Bifenthrin | pyrethroid | 6.4 | 6.5 a | 9.5 a | 1,578.3 a | -15.4 |

| Transform | sulfoximine | 1.25 | 3.3 a | 4.3 a | 1,642.8 a | 51.1 |

| Bidrin | organophosphate | 6 | 2.8 a | 3.3 a | 1,705.9 a | 114.7 |

| Bidrin + Diamond | OP + IGR | 6+6 | 2.3 a | 1.3 a | 1,592.7 a | 112.4 |

| P>F | P>0.05 |

Table 7. Impact of Selected Stink Bug Management Options on Secondary Tarnished Plant Bug Control 14 Days after Application in Belle Mina (2020)

Means within a column followed by a common letter are not significantly different (FPLSD P=0.05).

| Treatment | Class of Chemistry | Rate/Acre (oz) | % Dirty Bloom | Lint/A | Lint/A vs UTC |

|---|---|---|---|---|---|

| Untreated | none | 18.4% a | 1,579.7 a | ||

| Brigade | pyrethroid | 6.4 | 23.0% a | 1,508.9 a | -70.8 |

| Delta Gold | pyrethroid | 2.6 | 18.0% a | 1,612.8 a | 33.1 |

| Bidrin | organophosphate | 6 | 4.3% b | 1,711.0 a | 131.4 |

| Orthene | organophosphate | 12 | 6.3% b | 1,687.9 a | 108.2 |

| P>F | P>0.001 |

Table 8. Evaluation of Bt Technologies to Manage Bollworms in Prattville (2020)

Means within a column followed by a common letter are not significantly different (FPLSD P=0.05).

| Technology | Variety | Percent Damaged Structures (n=25) Squares | Percent Damaged Structures (n=25) Blooms | Percent Damaged Structures (n=25) Bolls | Percent Damaged Structures (n=25) Total | Lint/A vs Non-Bt |

|---|---|---|---|---|---|---|

| Non-Bt | PHY 425 | 10% a | 4% a | 16% a | 10% a | |

| Bollgard 2 | DP 1646 | 0% b | 1% a | 2% ab | 0.8% b | 423.7 a |

| Bollgard 3 | DP 2055 | 0% b | 0% a | 1% b | 0.3% b | 155.2 b |

| Widestrike 3 | PHY 400 | 0% b | 0% a | 0% b | 0% b | 325.2 ab |

| P>F | P>0.001 |

Trial Two. A second trial was conducted to evaluate the secondary effects of stink bug treatments on TPB management. Plots were sprayed and the percentage of TPB damaged dirty blooms found on 30 row feet was recorded. As expected, the pyrethroids did not provide protection from TPB. However, the organophosphates provided significant reductions of dirty blooms (table 7). The initial goal of this study was to determine the efficacy of the products on stink bugs, but no differences were found between treatments and the untreated check (data not shown), likely due to inadequate plot size (four rows). Because of this, it can be assumed that any treatment trends for yield are likely related to plant bug injury.

Evaluation of Bt Technologies for Bollworm Management. A trial was done at the Prattville Agricultural Research Unit (PARU) in Prattville, Alabama, to monitor the efficacy of Bt cotton technologies against bollworms. Cotton was planted on May 7 to ensure that it would be blooming during the peak bollworm flight in late July. Scouting for eggs was done during the peak flight window to assess the potential bollworm pressure in the trial. When scouted for damage, 25 squares, 25 blooms, and 25 bolls were assessed in each plot for bollworm damage and/or larvae. A final damaged boll count per 60 row feet was made after defoliation and prior to harvest.

Damage evaluations were made after the peak bollworm flight date (August 10) to evaluate the level of protection provided by Bollgard 2 (Cry1Ac+Cry2Ab), Bollgard 3 (Cry1Ac+Cry2Ab+Vip3A), and Widestrike 3 (Cry1Ac+Cry1F+Vip3A). Overall, pressure was low in this trial; however, the Bt technologies provided significant protection in terms of damaged fruiting structures and yield compared to the non-Bt check (table 8, figure 5). Results in this study show that Bt technologies still provide good control of bollworms in Alabama, at least in low to moderate pressure situations.

Figure 5. Total number of stink bug injured bolls (out of 240 total) collected from a trial in Prattville, Alabama (2020).

Figure 6. Total number of damaged bolls (and % reduction compared to non-Bt) found just prior to harvest in Prattville, Alabama (2020).

Establishment of Bollworm Sentinel Plots on Research Farms Throughout Alabma. Bt sentinel plots were established on research stations across Alabama to monitor the in-season efficacy of 2- and 3-gene Bt technologies against bollworms. Plots were planted as nonreplicated 4-row strips at least 100 feet long and were managed for bug pests (plant bugs, stink bugs) using insecticides that do not have activity on bollworms. At the end of the season, a damaged boll count was done to determine how well each technology protected cotton compared to the non-Bt check (figure 7). In 2020, WideStrike3, TwinLink Plus, Bollgard 2, and Bollgard 3 Bt technologies provided excellent protection against bollworms in all locations (table 9). These sentinel plots support the recommendation to plant Bt varieties that have the highest yield potential on a given farm, regardless of the Bt technology, as each currently provides adequate control of bollworms.

Figure 7. Damaged bolls collected from Bt sentinel plots in Brewton, Alabama (2020).

Table 9. Number of Damaged Bolls Found Prior to Harvest in Bt Cotton Sentinel Plots Planted at Five Research Stations across Alabama (2020)

| Technology | Number of Bollworm-Damaged Bolls per 100 Row eet Prattville | Number of Bollworm-Damaged Bolls per 100 Row eet Fairhope | Number of Bollworm-Damaged Bolls per 100 Row eet Brewton | Number of Bollworm-Damaged Bolls per 100 Row eet Headland | Number of Bollworm-Damaged Bolls per 100 Row eet Shorter | Number of Bollworm-Damaged Bolls per 100 Row eet Average |

|---|---|---|---|---|---|---|

| Non-Bt | 18.9 | 8.7 | 100.0 | 8.5 | 7.0 | 28.62 |

| WideStrike | 4.5 | 1.7 | 20.3 | 2.3 | 2.0 | 6.16 |

| WideStrike 3 | 0 | 0 | 0 | 0 | 0 | 0 |

| TwinLinkPlus | 0 | 0 | 0 | 0 | 0 | 0 |

| Bollgard 2 | 0 | 0 | 0 | 0.7 | 0 | 0.14 |

| Bollgard 3 | 0 | 0 | 0 | 0.2 | 0 | 0.04 |

Bt Resistance Monitoring

Monitoring Bollworm for Resistance to VIP Bt Technology. A block of non-Bt field corn was planted on research stations across Alabama to collect natural populations of bollworms to be screened for resistance to the VIP technology (Bollgard 3, WideStrike 3). Populations were collected and shipped to North Carolina State University to be screened against the VIP3Aa39 protein in the laboratory. The amount of VIP protein needed to kill 50 percent of the field population was compared to the amount needed to kill 50 percent of a lab colony that had never been exposed to the protein before testing. The tests showed that bollworm populations from Alabama in 2020 were as susceptible to the VIP protein as the lab colonies (table 10). This confirms that we do not have VIP resistance as of 2020.

Table 10. Resistance Ratios of Field-Collected Populations of Bollworms Collected from Non-Bt Field Corn across Alabama (2020)

*Resistance Ratio = field collected population LC50 / lab population LC50

Data from D. Reisig, NCSU

| Bollworm Population | Source | LC50 (ug/cm2) | Resistance Ratio* |

|---|---|---|---|

| Susceptible | Benzon (Lab) | 1.22 | |

| Susceptible | Lab SS-Tx | 0.38 | |

| Fairhope, AL | Non-Bt Corn | 0.44 | -3 |

| Prattville, AL | Non-Bt Corn | 0.34 | -4 |

| Brewton, AL | Non-Bt Corn | 0.38 | -3 |

| Belle Mina, AL | Non-Bt Corn | 0.22 | -6 |

Establishment of Sentinel Corn Plots to Monitor Bollworm Resistance to Bt Technologies. Four Bt corn varieties and one non-Bt variety were planted at the Tennessee Valley Research and Extension Center in Belle Mina, Alabama, to monitor in-season bollworm damage. Each variety was planted into nonreplicated strips four rows wide and 300 feet long at three planting dates, each two weeks apart. At the R3 growth stage, the number of live larvae found in 100 ears was recorded for each plot (table 11). At the R5 growth stage, the number of damaged kernels in 100 ears was recorded. Unlike in cotton, escaped bollworms are commonly found in 2-gene Bt corn. This is likely due to higher pressure in corn compared to cotton and differences in Bt expression between the crops.

Table 11. Number of Live Larvae Found in Bt and non-Bt Corn Planted across Three Planting Dates in Belle Mina (2020)

| Technology | Bt Proteins | Number Live Larvae per 100 Ears Plant Date 1 | Number Live Larvae per 100 Ears Plant Date 2 | Number Live Larvae per 100 Ears Plant Date 3 |

|---|---|---|---|---|

| Non-Bt | None | 75 | 77 | 80 |

| VT Double Pro | Cy1A + Cry2Ab2 | 39 | 58 | 31 |

| Trecepta | Cry1A + Cry2Ab2 + Vip3A | 0 | 0 | 0 |

| Leptra | Cry1F + Cry1Ab + Vip3A | 0 | 0 | 0 |

| Agrisure Viptera | Cry1Ab + mCry3A + Vip3A | 0 | 0 | 0 |

Scott Graham, Extension Specialist and Assistant Professor, Entomology and Plant Pathology, and Ron Smith, Visiting Professor, both with Auburn University

New February 2021, 2020 IPM Projects Advancing Alabama Cotton Production, ANR-2735