Farming

Accurate seed metering is one of the most important aspects of successful planter performance. This publication covers different types of available electric drive options for seed meters along with their advantages and important considerations before purchasing.

A seed meter is a critical component on row crop planters that helps in achieving the target seeding rate (seeds per acre) and maintaining the desired seed-to-seed spacing within the row. The drive mechanism for seed meters can be classified into three different types: ground, hydraulic, and electric.

Traditionally, seed meters on row crop planters are driven mechanically using a ground wheel and a combination of chains, sprockets, and shafts (figure 1a). The ground wheel turns the drive shaft, which is connected through a combination of chains and sprockets to the main (driven) shaft. The main shaft uses a chain drive to further rotate the seed meters on individual row units. The target seeding rate on these planters is achieved by manually selecting the appropriate gear ratio (sprocket sizes) between the drive and driven shafts.

Figure 1. Examples of (a) a traditional ground drive and (b) a hydraulic drive and other main components used for driving seed meters on row crop planters.

With adoption of GPS and precision agriculture in the 2000s, hydraulic drives were introduced for row crop planters to improve seeding performance. On these planters, the main shaft is driven using a hydraulic motor (figure 1b) instead of a ground wheel. Planters equipped with hydraulic drives offer capabilities such as setting and adjusting seeding rates in real time from the tractor cab and implementing variable-rate seeding prescriptions. Hydraulic drive planters can also be equipped with row clutches, enabling automatic section control capabilities. This feature enables individual planter row units to automatically turn off in areas that are already planted, thereby reducing overlap and facilitating efficient seed use.

In recent years, electric drives have become increasingly popular on modern row crop planters. They provide advanced seeding capabilities, such as individual row control, variable-rate seeding, turn compensation, and faster planting speeds, while maintaining the desired seeding rate and uniform seed spacing.

Advantages of Electric Drives

While the hydraulic drive typically replaces the ground wheel and a few other drive components, electric drives completely replace all major drive components, such as chains, shafts, and sprockets on a planter, and they mount directly to the seed meter on each row unit. Electric drives offer several advantages over traditional ground or hydraulic drives used for seed metering:

Precision population control. Electric drives provide precise control over the seed population, as the seeding rate can be easily controlled and adjusted through the in-cab monitor.

Improved seed singulation and spacing. Electric-drive seed meters have enhanced seed metering and singulation, resulting in more precise and uniform seed spacing within the row.

Individual row shut-off. Electric drives enable row shut-off capabilities, allowing individual planter row units to be manually or automatically turned off at headlands, outside field boundaries, or in previously planted areas, resulting in improved seeding efficiency.

Curve compensation. Electric-drive seed meters can perform curve compensation, allowing each planter row unit to adjust and maintain a consistent seeding rate and uniform seed-to-seed spacing when planting in curved or turn rows.

Reduced maintenance. Electric drives are easier to maintain as they have fewer moving parts, such as chains, sprockets, or shafts, that require regular maintenance and inspection.

Variable-rate seeding capabilities. Seed meters equipped with electric drives can perform variable-rate seeding, where the seeding rate for each row unit can be varied in real time based on a prescription map or manually through the in-cab display/monitor.

Higher seeding rates and speeds. Electric-drive seed meters can plant at higher seeding rates without sacrificing metering or singulation performance. Additionally, they can be used with advanced seed delivery systems, such as flighted or brush belts, to plant at faster planting speeds (up to 12 mph).

Easier calibration and troubleshooting. Electric-drive seed meters can be calibrated and primed easily through the in-cab planter display. Real-time planting feedback also helps in troubleshooting individual seed meters or other metering issues before or during planting.

Types of Electric Drives

There are two main types of electric drive options available for row crop planters: an integrated electric drive and seed meter or an electric drive that can be retrofitted to existing seed meters. The difference between the two options is whether it replaces all the seed metering components or only the drive mechanism on a planter.

Integrated Electric Drive and Seed Meter

Figure 2. (a) Example of an electric-drive seed meter (Precision Planting vDrive and vSet) and its internal metering components; (b and c) front and back views of the same electric seed meter installed on a seed hopper.

This is the most common and popular option for electric-drive seed metering on planters where an electric motor (drive) is integrated with the seed meter body (figure 2). These electric-drive seed meters completely replace all traditional drive and seed metering components, including the ground or hydraulic drive, main shaft, seed meter housing, seed disks (plates), chains, and sprockets. These electric drive seed meters can be mounted to the existing or new hoppers and include precision metering components, such as seed disk (plate), singulator/doubles eliminator, and knockout wheel, that can be easily changed based on the crop type. These electric drives are available as both a factory-installed option on new planters and as a retrofit option for older planters.

Electric Drive Only

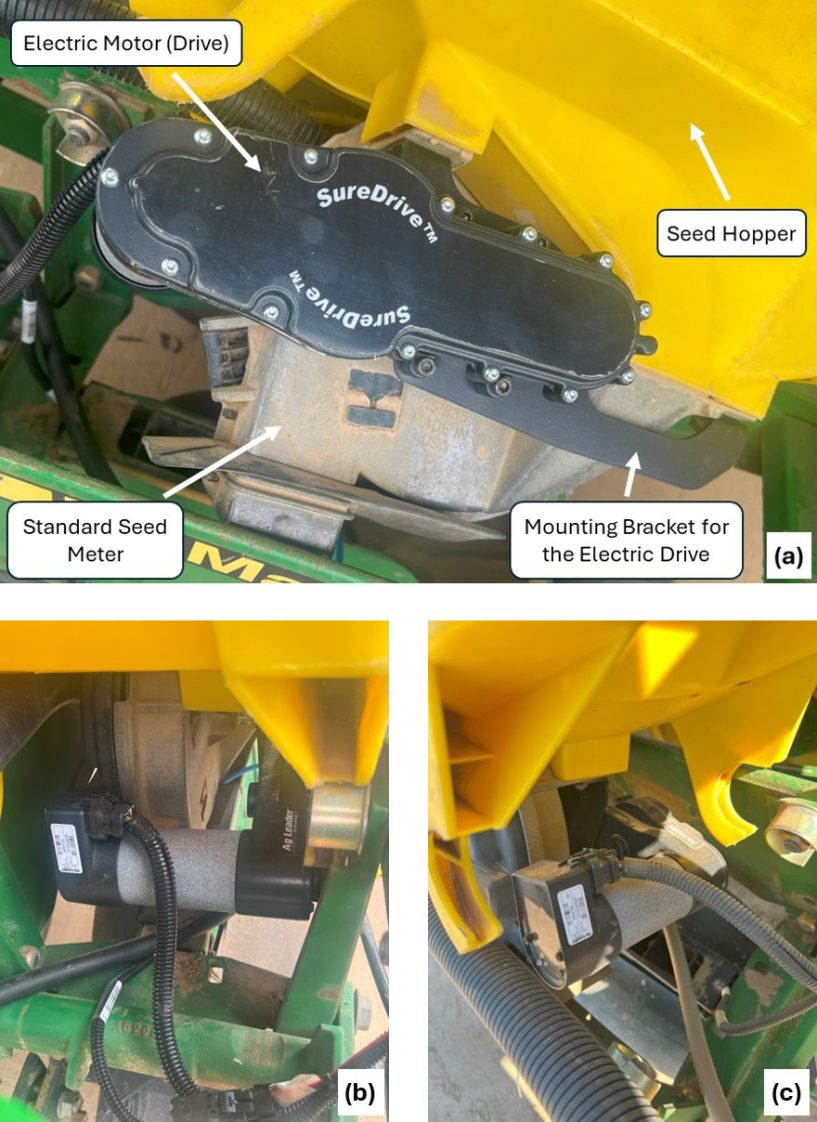

In this option, only the primary drive components, including the ground or hydraulic drive, main shaft, chains, and sprockets, are replaced with electric drives on each row unit, while the existing seed metering components, including the seed meter and disk (plate), remain the same (figure 3). These electric drives are mostly available as retrofit options for older planters, without requiring changes to the existing seed meters. They provide similar capabilities as fully integrated electric-drive seed meters, such as adjusting seeding rates from the in-cab monitor and performing variable-rate seeding using a prescription map.

Figure 3. (a) Example of an electric drive (AgLeader SureDrive) configured with an existing John Deere standard seed meter; (b and c) different side views of the electric drive installed on a seed hopper.

It is important to note that the seed metering performance when using these drives requires proper seed meter setup along with additional components (based on crop type), such as a singulator/doubles eliminator, knockout wheel, etc., in the seed meter to improve singulation performance.

This electric-drive option is relatively cost-effective compared to the fully integrated electric seed meter. It is also a good option for growers who want to keep their existing seed meters and/or may not require advanced seeding capabilities on their planters but can benefit from the ability to set the desired seeding rate and make any on-the-go rate adjustments from the cab.

Both electric-drive options listed here require either an existing or a new in-cab monitor (depending on the manufacturer) to control and operate the seed meters on each row unit. The full system usually consists of an electric drive and row control module (RCM) on each row unit, a main planter harness that connects the RCM on each row unit to an electronic control unit (ECU), and an in-cab monitor, which is connected to the ECU via another harness or ISOBUS connection. The ECU is a central unit that connects the RCMs and the in-cab monitor, performing the primary function of transmitting and receiving data to/from the electric drives and the monitor. The entire system, including the ECU, RCMs, and electric drives, is powered by either the tractor battery or an external power source, depending on the system’s voltage requirements.

Considerations for Upgrading to Electric Drives

Several factors should be considered before upgrading to electric drives, as reverting to traditional ground or hydraulic drives afterward is generally not a straightforward process. Electric drives permanently replace many mechanical components on a planter (which are usually removed to reduce planter weight), and these components may not be available later once the planter has been upgraded to electric drives. Following are some main aspects that need to be considered:

Cost. Electric drives typically incur higher upfront costs than traditional mechanical systems. Also, there may be some additional costs associated with the annual maintenance and upkeep of the system that must be considered before investing in it. It is advisable to check with the manufacturer about any additional fees or subscriptions required for unlocking and utilizing advanced features, such as curve compensation.

Compatibility. While multiple electric-drive options are currently available in the market, not all of them are compatible with each planter type and model. Be sure to check with the manufacturer before investing in a particular electric-drive option to determine if it is compatible with your specific planter model and other equipment.

Power source. Depending on the manufacturer, the power requirement for electric drives can vary from 12 to 48 volts. In some cases, utilizing power from the tractor may not be an option. An additional power source, such as a generator on the planter or an alternator, may need to be installed to provide adequate voltage to the system.

Training. For proper functioning, electric drives need to be configured correctly using the in-cab monitor. The operator may need to be trained on the proper setup and operation of electric-drive seed meters. This is particularly important when troubleshooting seed meters during planting or replacing internal components.

Maintenance. Electric drives require less maintenance than traditional systems; however, regular inspections and potential repairs may still be necessary to ensure proper functioning. Wiring harnesses and other electrical components are prone to damage from rodents, weather during storage, or pinched wires, among other factors. Therefore, they generally require a basic system checkup and maintenance at the beginning of the planting season.

Downtime. Potential planter downtime due to electrical issues, GPS signal acquisition, or other maintenance needs can be considerably more for electric drives than for traditional mechanically driven systems. Unlike mechanical seed metering systems, where drive or meter components can be easily replaced, troubleshooting issues with electric drives may sometimes require assistance from a trained support specialist or the manufacturer.

Commercially Available Options for Electric Drives

Several planter and technology manufacturers currently offer electric drives or electric-drive seed meters as factory-installed options for newer planters or as retrofit options for existing planters. These options are listed below (see the respective websites).

- vDrive and vSet (Precision Planting)

- SureDrive (AgLeader)

- MaxEmerge 5e (John Deere)

- Blue Drive (Kinze)

- AirVAC Metering System (Horsch)

- ValoTerra (Monosem)

- Graham Electric Planter (Graham)

Simerjeet Virk, Extension Specialist, Associate Professor, Biosystems Engineering, Auburn University

Simerjeet Virk, Extension Specialist, Associate Professor, Biosystems Engineering, Auburn University

New August 2025, Electric Drives for Seed Metering on Row Crop Planters, ANR-3175