Crop Production

Proper setup, maintenance, and operation to peanut harvest equipment (digger-shaker-inverter and combine) are important for attaining optimal in-field performance and maximizing harvest efficiency.

Improper setup and operation of the harvest equipment and prevalent crop and field conditions can incur losses during peanut harvest.

While some losses during peanut harvest are common, excessive losses can significantly reduce peanut yields and profits if not managed appropriately. Though harvest losses cannot be eliminated, they can be reduced considerably; therefore, it is important to assess and understand the level of losses so appropriate adjustments to harvest equipment settings, operational parameters, or harvest decisions can be made to keep these losses to a minimum. The following steps outline a simple procedure for estimating losses from the number of pods on the ground after combining:

Procedure for Calculating Harvest Loss

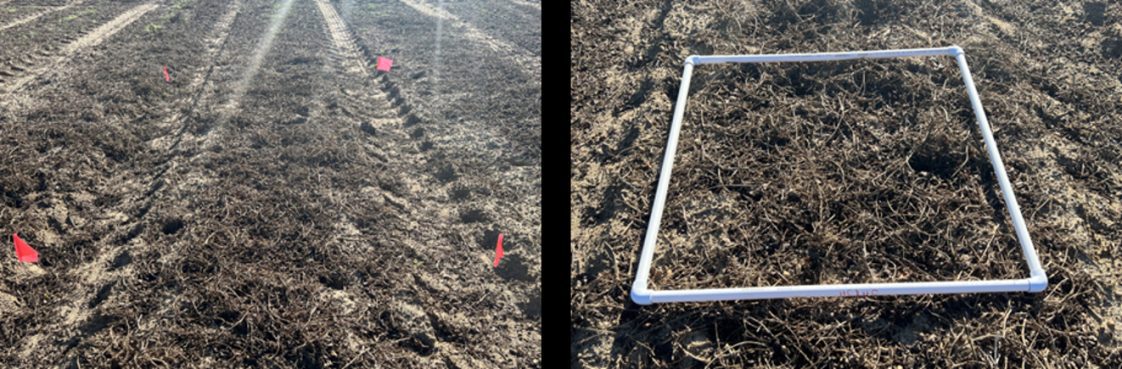

1. Measure and mark a sampling area behind the combine using a tape measure and flags or a small PVC frame (figure 1). The sampling area should be at least two rows wide by three feet long to provide an adequate estimate of harvest loss. Note that the larger the sampling area, the more accurate the loss estimation will be. Loss estimations are also more accurate when performed across the entire width of the windrow.

Figure 1. The sampling area can be marked with a tape measure and flags or a PVC frame.

2. Record the length and width of the marked area or the sampling device and calculate its area in square feet. Remember, if you are measuring a certain length of the windrow, you are working with two peanut rows and a sample width of 72 inches or 6 feet based on 36-inch row spacing.

3. Carefully count the total number of pods on the ground within the selected area (whether marked using flags or within the sampling device). Repeat the same process at least three to five times and sample different areas within the field to account for variability and compute an average value for the number of pods on the ground. Make sure to include only mature peanuts/pods in these counts, as it is common to have a few overmature or unfilled pods (pops) that should not be counted and included in the loss calculations.

Calculate the estimated harvest loss in pounds per acre by using the formula below:

HL = (N × W × 96)/A

Where HL is the harvest loss in pounds per acre (lb/ac)

N is the average number of pods present on the ground (computed in step 3 above).

W is the average weight per pod in grams (g) and is estimated to be 1.8 g for Virginia-type peanuts and 1.2 g for runner-type peanuts.

A is the area (ft2) sampled or the area of the sampling device.

96 is the unit conversion factor to obtain harvest loss in lb/ac.

Note: For a more accurate estimate of harvest loss, record the actual weight of the pods within the sampled area instead of using the total number of pods multiplied by the average pod weight for the peanut variety (N × W). Also, this method does not account for pod moisture, which is not easily measured in the field. However, if moisture is known, the values can be adjusted accordingly for a more accurate harvest loss estimate.

Example Harvest Loss Calculation: The average number of pods counted during multiple samplings across the field using a 6 ft × 6 ft PVC frame was 15. What are the estimated harvest losses, assuming Virginia-type peanuts?

Using the information provided above in the formula listed in step 4:

Average number of peanuts present on the ground, N = 15

Weight per pod for Virginia peanuts, W = 1.8 g

Area sampled, A = 36 ft²

HL = (15 × 1.8 × 96) ÷ 36 = 72 lb/ac

The total harvest losses are estimated to be 72 pounds per acre.

4. After assessing the harvest loss, the operator should determine if the average loss is within an acceptable range (less than 10 percent of the average yield) or higher. Remember, harvest loss can vary based on peanut variety, field conditions, etc., and what is acceptable could change based on the prevalent crop and field conditions. Also, some harvest losses are common and cannot be eliminated even with the optimal combine settings. If the harvest losses are high, equipment settings should be adjusted appropriately per the recommendations provided by the manufacturer in the operator’s manual. When adjusting different settings to reduce losses, change only one setting at a time to determine how it affects harvest losses and make any necessary adjustments accordingly.

5. After adjusting the combine each time, repeat steps 1 through 4 to obtain a new estimate of the harvest losses, and continue evaluating and optimizing the combine settings based on the field and crop conditions at harvest. The goal is to follow this process until the peanut harvest losses are minimized as much as possible.

Online Harvest Loss Calculators

A few useful calculators are available online that can be used to estimate peanut harvest losses. Using steps 1 through 3 in the previous section, count the number of pods on the ground within a known area , but the actual calculations can be skipped. Instead, this information, including row spacing, length and width of the area, and peanut variety/type, along with the total number of pods present in the ground within the sampled area, can be entered into a calculator to obtain an estimate of the harvest losses. Some calculators may require additional information, such as harvest equipment model or frame size, to provide a more accurate estimate.

A few useful calculators are available online that can be used to estimate peanut harvest losses. Using steps 1 through 3 in the previous section, count the number of pods on the ground within a known area , but the actual calculations can be skipped. Instead, this information, including row spacing, length and width of the area, and peanut variety/type, along with the total number of pods present in the ground within the sampled area, can be entered into a calculator to obtain an estimate of the harvest losses. Some calculators may require additional information, such as harvest equipment model or frame size, to provide a more accurate estimate.

A web-based tool, Peanut Harvest Loss Calculator, is available from Kelley Manufacturing Company (KMC). Similarly, Peanut Yield Estimator is available online from the Clemson Precision Agriculture team.

Other Considerations

Regardless of whether someone opts to use the procedure provided here or an online calculator, an important point to remember during peanut harvest loss estimations is that this method provides an estimate of the total aboveground harvest losses, including the losses that have occurred during digging and combining as well as any pod losses due to disease or insect pressure. The method outlined in this publication or the online calculators can also assess aboveground digging losses separately while digging peanuts. However, there could also be an equal number or more pods below the ground, which would need separate measurements and can make assessing belowground losses cumbersome and time consuming.

To assess peanut harvest losses incurred only by the combine during harvest and make necessary adjustments to fine-tune combine settings, a common method also employed by the harvest equipment manufacturers is to throw a relatively flat catch pan or similar device under the material coming out from the back of the combine and count the number of pods in or on the pan. Then, the harvest loss is estimated again similarly by entering the information in the harvest loss formula or an online calculator.

Regardless of the brand and condition (used or new) of the harvest equipment, the essential consideration for peanut growers is to take the time to assess the harvest losses associated with the harvest equipment, especially at the beginning of the season and periodically during the season to avoid any unnecessary yield losses and get the most peanuts out of the fields.

Simerjeet Virk, Extension Specialist, Associate Professor, Biosystems Engineering, and Kris Balkcom, Assistant Extension Professor, Crop, Soil, and Environmental Sciences, both with Auburn University

Simerjeet Virk, Extension Specialist, Associate Professor, Biosystems Engineering, and Kris Balkcom, Assistant Extension Professor, Crop, Soil, and Environmental Sciences, both with Auburn University

New November 2024, Estimating Peanut Harvest Losses, ANR-3113