Aquaculture

Low-cost salt mixtures can serve as an alternative to commercial sea salts during the low-salinity acclimation process of Pacific white shrimp production.

Figure 1. Pacific white shrimp are cultured by farmers in west Alabama using low-salinity water.

Pacific white shrimp, Litopenaeus vannamei, are the most heavily cultured shrimp species in the world due to their ability to adapt to a wide range of salinities (figure 1). While native to the coast of Southern California south to Peru, these shrimp have been produced successfully in low-salinity water by a small number of farmers in west Alabama for over 20 years. In recent years Alabama has ranked third in the United States in commercial shrimp production behind Texas and Florida, with production reaching up to 300,000 pounds per year.

Until now, artificial sea salts that are needed to help the shrimp acclimate from a high salinity to a low salinity environment were only available commercially. Research at Auburn University, however, has shown a low-cost salt mixture (LCSM) to be a viable alternative to the more expensive commercial sea salts.

Growing Pacific White Shrimp in Alabama

Pacific white shrimp are well suited to farms within Greene, Sumter, or Lowndes Counties that have access to a low-salinity aquifer located in west Alabama. Producers use wells to fill earthen ponds with the low- salinity water from this aquifer.

The salinity of the aquifer ranges widely depending on geographical location but is usually in the 2 to 11 parts per thousand (ppt) range, much less than the salinity of seawater (approximately 34 ppt). While the salinity of this groundwater is acceptable for shrimp production, farmers still must add large amounts of fertilizers containing potassium and magnesium to raise the ions in the water to optimal concentrations for growing shrimp.

Producers purchase shrimp postlarvae (baby shrimp) from commercial hatcheries in Florida or Texas and transport them to Alabama in live hauling tanks (figure 2) with water salinity of 30 ppt. Upon arrival at the farm, producers begin the process of acclimating shrimp from the high salinity in which they arrive to the lower salinity (typically 2 to 6 ppt) of production ponds on the farm (figure 3).

Acclimation involves transferring the shrimp initially to nursery tanks, which are usually large circular or raceway tanks located in greenhouses or on the pond bank. These tanks are prepared beforehand with water from the production pond along with artificial sea salt products that raise the water’s salinity to 30 ppt. Over the course of 5 to 10 days, farmers slowly exchange the nursery tank water with low-salinity pond water until the shrimp are acclimated to the salinity of production ponds on the farm. Shrimp are then transported from nursery tanks and stocked into production ponds (figure 4).

In low-salinity pond culture in Alabama and other states, commercial artificial sea salts are typically used only for this nursery phase of production. In states farther north that use indoor production systems, they are used for the entire production cycle. Either way, artificial sea salts can be quite expensive.

- Figure 2. Shrimp postlarvae are transported from hatcheries on the coast to west Alabama shrimp farms.

- Figure 3. Upon arrival at the farm, shrimp postlarvae are acclimated to the salinity and temperature of nursery tanks.

- Figure 4. Following acclimation, shrimp postlarvae are transported from nursery tanks to production ponds where they are released for grow out.

Viability of Low-Cost Salt Mixtures

Artificial sea salt mixtures carry the primary ions necessary for normal physiological demands of the Pacific white shrimp, including sodium (Na), potassium (K), calcium (Ca), and magnesium (Mg). The Na, K, Ca, and Mg concentrations in 1 gram per liter (g/L) (1 ppt) diluted seawater are shown in table 1. This table can be used to determine the concentrations of these ions required at a farm by multiplying the ionic concentration by a particular salinity. For example, at 6 ppt (6 g/L), the Mg concentration can be determined by multiplying 39 (from table 1) times 6 (salinity of diluted seawater) to give 234 mg/L.

Table 1. Concentrations of Sodium, Potassium, Calcium, and Magnesium in 1 ppt Salinity Solution Made from Commercial Artificial Sea Salt

| Mineral Ions | Concentration (mg/L) |

|---|---|

| Sodium (Na) | 300 |

| Potassium (K) | 11 |

| Calcium (Ca) | 11 |

| Magnesium (Mg) | 39 |

The requirements for individual ions (and the ratios between some of these ions) are not well understood and can vary depending on the ionic composition of the culture water. Because of this, farmers have chosen primarily to use artificial sea salt products to ensure that concentrations of these ions are optimal for shrimp acclimation.

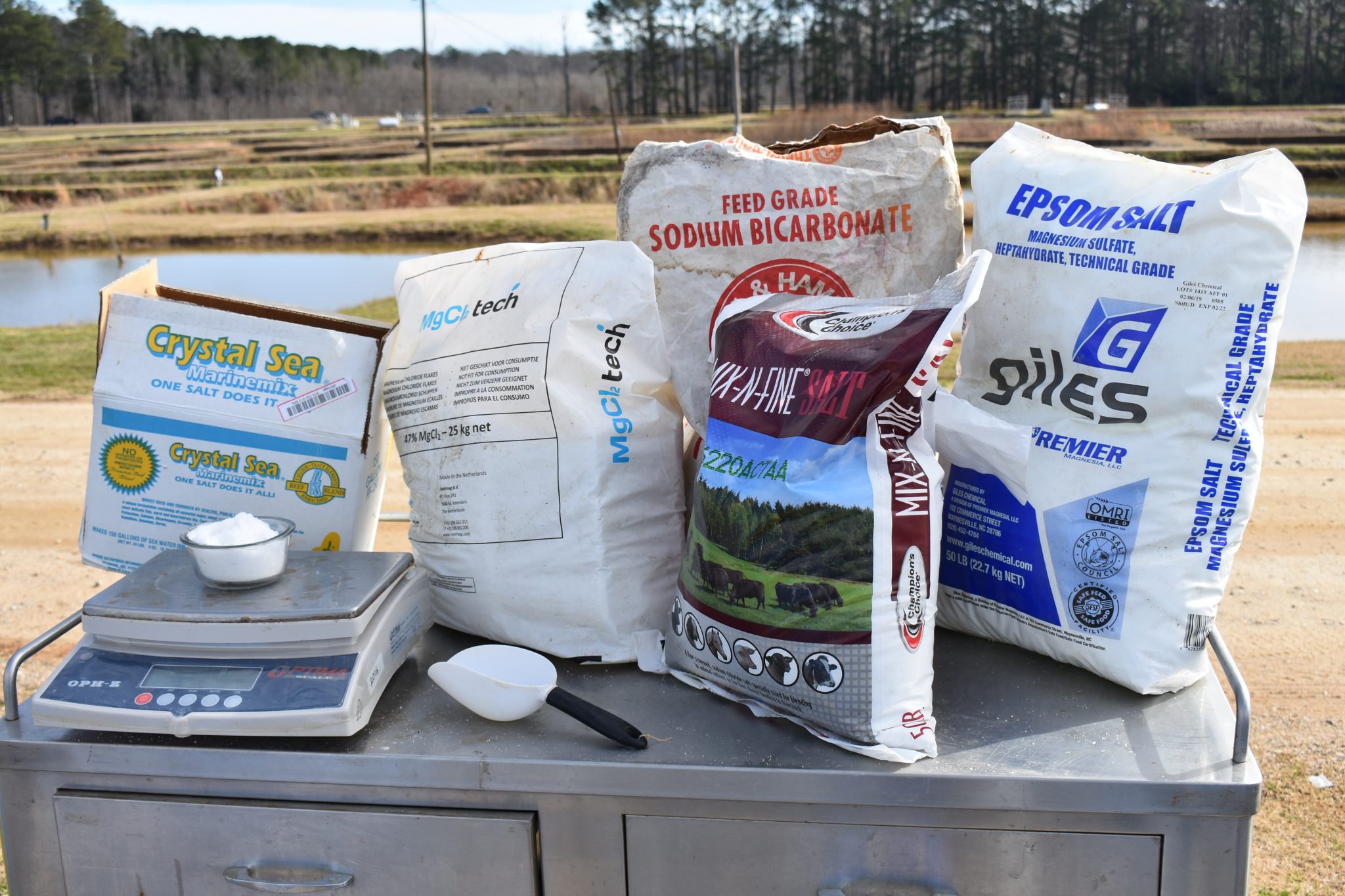

Figure 5. Researchers at Auburn University and the Alabama Fish Farming Center have investigated a low-cost salt mixture as an alternative to commercially available artificial sea salts.

Researchers at Auburn University, however, have examined a low-cost salt mixture (LCSM) as a potential alternative to more expensive commercially available sea salts for the nursery phase of production on low- salinity shrimp farms in Alabama. They investigated various weights and mixtures of individual salt products for use in place of commercial products such as Instant Ocean and Crystal Sea Marinemix (figure 5).

The low-cost salt mixture (LCSM) was formulated to yield Na, K, Ca, and Mg concentrations closely comparable to that of diluted seawater using agriculture- grade sodium chloride, magnesium chloride, magnesium sulfate, muriate of potash (potassium chloride), calcium chloride, and sodium bicarbonate. (See table 2, figure 5, and box 1.) Due to the variation of ionic concentrations at different salinities, farmers must adjust the amount of salt compound in their culture water based on the target salinity and water volume of their nursery acclimation tanks.

Research results revealed that both postlarval and juvenile Pacific white shrimp raised in this LCSM performed as well as control shrimp raised in culture water prepared from a commercial artificial sea salt at three different salinities (3, 6, 15 ppt). These results reflect the potential use of LCSM to replace artificial sea salts without compromising the growth and survival of shrimp in different production phases of inland low- salinity shrimp aquaculture.

Table 2. Composition of Low-Cost Salt Mixture to Obtain 1 ppt Salinity in 10,000 L (2,642 Gallon) Solution

Based on the product details from the manufacturer/distributor

aChampion’s Choice, Cargill, Inc., Minneapolis, MN

bNedmag B.V., Veendam, Netherlands

cGiles Chemical, Waynesville, NC

dMosaic Global Sales, LLC, Lithia, FL

e Industrial Chemicals, Inc., Birmingham, AL

fChurch and Dwight Co., Inc., Ewing, NJ

| Source | Purity | Percent Ion | Amount (Metric) | Amount (Imperial) |

|---|---|---|---|---|

| Sodium chloridea | 99.9 (95% as NaCl) | 39% Na in NaCl | 7.7 kg | 16.98 lb. |

| Magnesium chlorideb | 47% MgCl2 | 26% Mg in MgCl2 | 1.0 kg | 2.20 lb. |

| Magnesium sulfatec | Mg = 9.8% S = 12.9% | 20% Mg in MgSO4 | 1.2 kg | 2.65 lb. |

| Muriate of potash (potassium chloride)d | 62% K2O equivalence | 83% K in K2O | 213.8 g | 0.47 lb. |

| Calcium chloridee | 43% CaCl2 | 36% Ca in CaCl2 | 0.7 L | 23.67 oz. |

| Sodium bicarbonatef | 27% Na in NaHCO3 | 60.6 g | 0.13 lb. |

Practical Use of LCSM

Producers of Pacific white shrimp must adjust salt calculations according to the purity levels of different commercial salt sources. The compositions in table 2, for example, are accurate only for the particular batch of ingredients available at the time to make these different salt mixtures.

The ionic concentration of the culture water also should be checked before stocking shrimp in both nursery and pond production systems. Differences in the solubility of various salt compounds are common due to variabilities in composition and other factors. It is, therefore, best to mix salt compounds thoroughly with fresh water at least 2 days before use to ensure a complete solution.

For Alabama producers of Pacific white shrimp, simplifying the formulation rather than balancing all the different ions and trace minerals found in commercially available artificial sea salt products provides a savings of approximately 50 percent in the cost of sea salt needed during the nursery phase of acclimation. Results reflect the potential of LCSM to replace commercially available artificial sea salts in the nursery phase of production for inland shrimp farmers before stocking earthen ponds.

Sample calculation to determine muriate of potash requirement to supplement K in low-cost salt mixture at 1 ppt salinity in a 10,000 L (2,642 gallon) solution

Step 1: K requirement for 10,000 L volume at 1 ppt salinity

The K level in seawater at 1 ppt salinity: 11 mg/L (table 1)

Amount of K in 1 L volume at 1 ppt salinity: 11 × 1 = 11 mg

Amount of K needed in 10,000 L at 1 ppt salinity: 11 × 10,000 = 110,000 mg (110 g)

Step 2: K in muriate of potash

The concentration of K in muriate of potash is expressed as K2O, and the percentage of K2O in muriate of potash is 62% (table 2).

Atomic mass unit (in g/mol) of interested elements: K = 39.1, O = 15.99, K2O = 94.2 (from the periodic table of elements)

The amount of K in K2O: ([39.1 × 20] ÷ 94.2) × 100 = 83%

Step 3: Quantity of muriate of potash

Required K quantity: 110 g (from step 1)

Required K2O quantity: 83% K in K2O (from step 2). To obtain 110 g K, 132.53 g K2O [(110 ÷ 83) × 100 = 132.53 g] is needed.

Required quantity of muriate of potash: 62% K2O in muriate of potash (table 2).

In order to obtain 132.53 g K2O, 213.76 g muriate of potash [(132.53 ÷ 62) × 100 = 213.76 g] would be required.

Harsha Galkanda-Arachchige, Graduate Research Assistant, D. Allen Davis, Professor, Anita M. Kelly, Extension Professor, Luke A. Roy, Associate Extension Professor, all in the School of Fisheries, Aquaculture, and Aquatic Sciences, Auburn University

Harsha Galkanda-Arachchige, Graduate Research Assistant, D. Allen Davis, Professor, Anita M. Kelly, Extension Professor, Luke A. Roy, Associate Extension Professor, all in the School of Fisheries, Aquaculture, and Aquatic Sciences, Auburn University

New August 2021, Pacific White Shrimp Farming in Alabama: Use of Low-Cost Salt Mixtures, ANR-2785